Jan 28, 2026|

From Fixed Capacity to Elastic Fulfillment: How JINGDONG Logistics’ LangzuTech Goods-to-Person System Redefines Smart Warehousing

- Modular, zone-based deployment allows warehouses to scale outputup or down with demand, reshaping fulfillment cost structures.

- Goods-to-person design leverages up to 12 meters of clear height, significantly increasing storage density and reducing warehousing cost per unit.

- Successfully deployed across apparel, pharmaceuticals, electronics, FMCG, and full-category warehouses with complex order profiles.

As e-commerce and omnichannel retail continue to evolve globally, logistics and supply chain operators are facing unprecedented operational complexity. Rapid SKU expansion, frequent assortment changes, and extreme order volatility, particularly during peak sales events, are placing growing pressure on traditional warehouse models built around manual labor and fixed capacity.

To address these challenges, JINGDONG Logistics has developed the LangzuTech Tote Handling, a Goods-to-Person (G2P) system.

An Integrated Goods-to-Person Architecture Built for Density and Accuracy

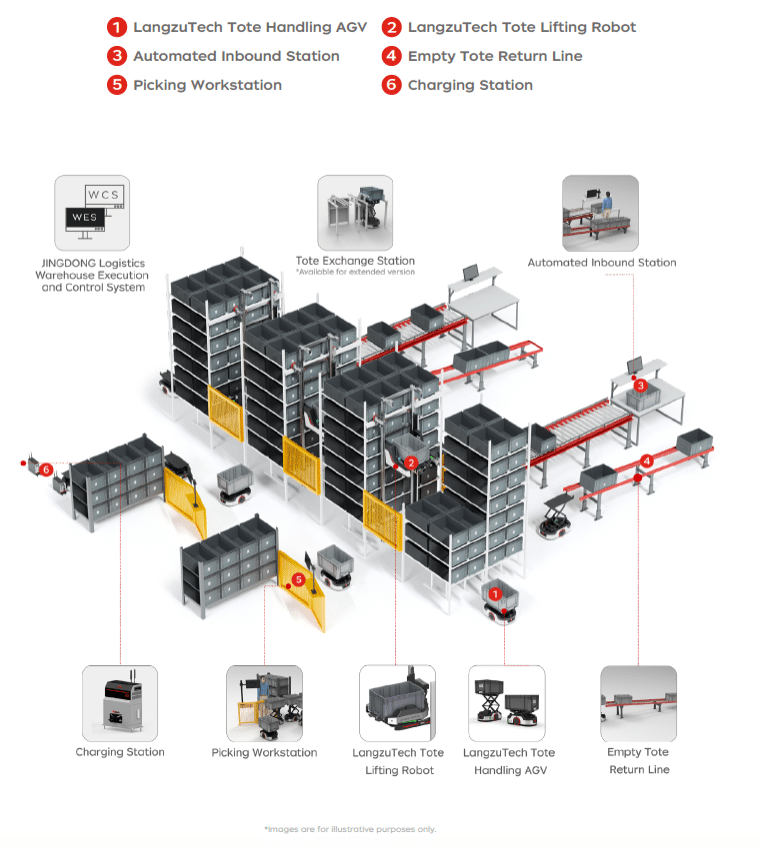

LangzuTech Tote Handling System is a fully integrated G2P solution that combines tote-handling AGVs, lifting robots, high-density three-dimensional racking systems, automated inbound and picking workstations, empty tote return lines, and centralized charging stations into a closed-loop operational flow.

Through intelligent spatial reconfiguration, the system maximizes the use of a clear height under 12 meters, enabling high-density storage that significantly increases space efficiency and lowers unit warehousing costs. Unlike traditional warehouses that rely on strict category-based zoning, it supports multi-SKU, multi-category storage within a single tote, minimizing consolidation and improving order assembly efficiency in mixed-order environments, while fully leveraging warehousing space.

Modular Deployment for Faster Time to Value

Unlike conventional automated warehouses that require large upfront investment and rigid capacity planning, LangzuTech Tote Handling System adopts a modular, building-block design. Warehouses can deploy the system by zone, implement it in phases, and scale capacity by flexibly adding or redeploying robots and workstations as demand fluctuates.

This allows operators to increase investment as their business grows. As a result, automation upgrades integrate smoothly into live operations, minimizing disruption while accelerating return on investment.

By shifting from labor-intensive, fixed-capacity models to a more agile, technology-driven framework, JINGDONG Logistics fundamentally reshapes the cost structure of fulfillment operations and lowers the entry barrier to intelligent warehousing for businesses of various sizes.

Proven Across Complex, Multi-Category and Regulated Environments

The solution has been successfully deployed across a wide range of industries, including apparel, e-commerce, pharmaceuticals, consumer electronics (3C), FMCG, and beauty.

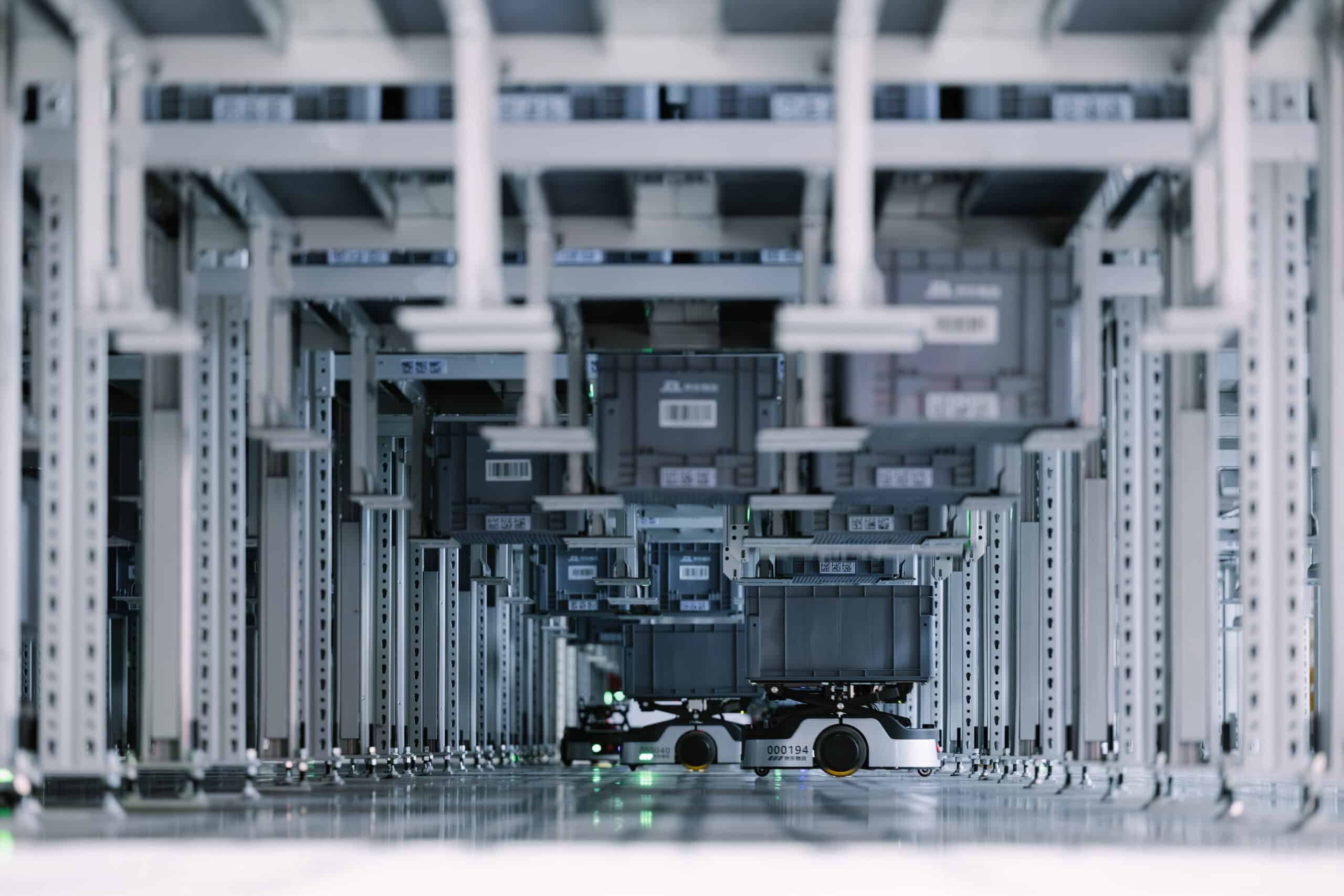

In large-scale apparel fulfillment centers, where rapid onboarding of new SKUs and fast shelving are critical, it enables five- to sixfold improvements in inbound shelving efficiency without expanding warehouse footprint. In one high-volume apparel operation, hundreds of robots operate collaboratively across dense storage aisles and multiple workstations, supporting daily outbound peaks of over 30,000 orders while significantly improving fulfillment speed and stability.

In pharmaceutical applications, LangzuTech Tote Handling System delivers both efficiency and compliance. Each product is assigned a unique traceability code when it arrives, enabling end-to-end inventory visibility. The system automatically manages storage rules for cold-chain, light-sensitive, and regulated products, while continuously monitoring temperature and humidity. Near-expiry inventory triggers automated alerts, eliminating the need for manual inspections. By leveraging high-density storage and robot-driven handling, a pharmaceutical warehouse using the solution has achieved:

- Up to 4× storage density on the same footprint

- 99% picking accuracy

- Up to50% reduction in per-order handling costs

Order consolidation across multiple downstream outlets further shortens outbound lead times and strengthens overall supply chain responsiveness. In pharmaceutical operations in China, a LangzuTech-powered warehouse feeds hundreds of downstream retail pharmacies in the Beijing region. Without having to expand warehouse footprint, the overall processing capacity has increased by approximately 600%, compared with pre-automation operations.

LangzuTech Tote Handling Solution has now entered a phase of large-scale replication and deployment, supporting JINGDONG Logistics’ broader vision of building efficient, resilient, and sustainable supply chains worldwide.

As JINGDONG Logistics continues to expand its global warehouse network, which now includes more than 130 overseas, bonded and direct mail facilities worldwide, the LangzuTech solutions provide a standardized, yet flexible automation foundation that can be adapted to diverse regulatory, operational, and industry environments.

JD.com Announces JD Museum

JD.com Announces JD Museum