Oct 22, 2020|

GSSC Series: JD Empowers Industries Through Supply Chain Solutions

by Hui Zhang

JD has helped the automotive and FMCG(fast moving consuming goods) industry improve efficiency through supply chain solutions, said Zhenhui Wang, CEO of JD Logistics, at the 2020 Global Smart Logistics Summit (GSSC) on Oct. 22.

The automotive industry is a complex industry with a long and multi-linked supply chain. The process of making a car which consists of tens of thousands of parts and components usually involves hundreds of suppliers, resulting in opaque information, inefficient supply chains, and excess inventory.

Relying on its strong supply chain capabilities, JD Logistics helped to improve the supply chain efficiency of a renowned domestic auto manufacturer. In order to do this, JD Logistics integrated different data into the auto manufacturer’s order distribution platform so as to solve the problem of upstream and downstream information fragmentation.

Additionally, JD Logistics incorporated capabilities such as intelligent inventory forecasting and enabling accurate replenishment recommendations to help the enterprise significantly reduce overall fulfillment costs and inventory by 30%, and increase the order fulfillment rate by 10%.

“We’re opening our technology to help different industries improve efficiency by utilizing technology to reduce cost and improve consumer experiences,” said Wenming Zhe, chief architect and head of logistics R&D at JD Logistics. “JD Logistics is offering strong technical support for various of industries and working together with them to improve people’s lives with technology.”

Wang noted that the industrial park of a FMCG enterprise usually covers a large area with many goods, personnel and vehicles working in the park. In the past, the management of such an industrial park has been a traditional manual management mode, with the scheduling of personnel, vehicles and goods relying on the experience of the park manager, and the transfer of information among different sections relying on printed or written documents. This piecemeal approach inevitably brought about problems such as low management efficiency, chaotic vehicle deployment, and more.

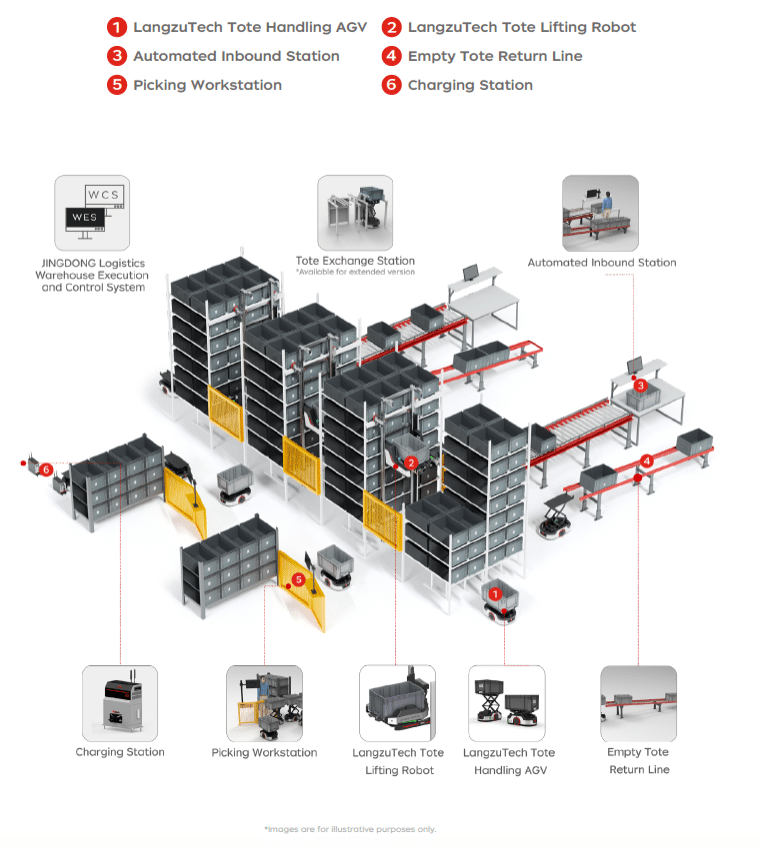

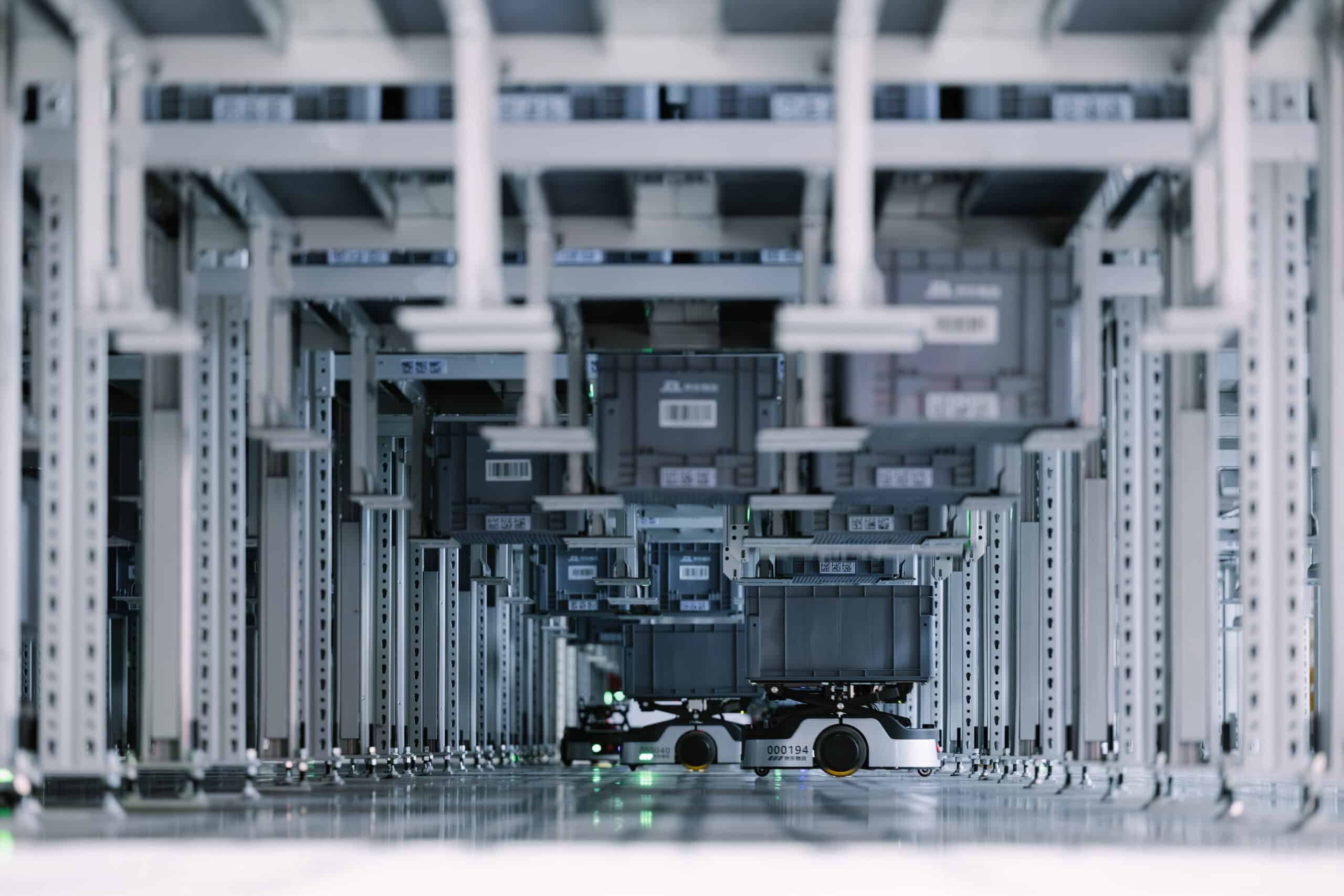

Now, JD Logistics has leveraged its technology such 5G, IoT and blockchain, which has been widely applied at JD’s Asia No. 1 Warehouse in Beijing, to help an FMCG enterprise in making their industrial park intelligent.

JD’s use of 5G in the park enabled the FMCG enterprise to dramatically increase the efficiency of its IoT fulfilment capacities on a large scale, facilitating instantaneous communication between human employees and smart machines, while enabling holistic monitoring of the site’s operations. The technology also enables real-time monitoring of location and routes for forklifts and pallets, and provides preemptive alerts if something abnormal arises.

E-signature chain is another technology that JD Logistics provided to the FMCG company. The E-signature chain utilized blockchain and digital signature technology to break through the traditional paper model, by implementing digital operations in order to help the company avoid inefficiency and wasted cost. The new system also radically improves the pain point of complicated document review and endless account settlement, ensuring that business transactions are secure and properly regulated.

The technology transformation provided by JD Logistics has fully automated the FMCG’s industrial park, saving 60% of labor costs and 50% of document management costs for the park.

“We leave complexity and difficulties to ourselves and simplicity and convenience to customers,” said Wang. “Through simple and optimized logistics technology products, we tackle complicated problems throughout the supply chains of different industries while improving circulation efficiency.”

GSSC Series: JD’s Smart Cloud Warehouse Project Helps Boost Local Industrial Economy

GSSC Series: JD’s Smart Cloud Warehouse Project Helps Boost Local Industrial Economy