Oct 22, 2020|

GSSC Series: Rise of China’s Supply Chain System Promotes Innovation Worldwide: Nobel Laureate

by Kelly Dawson

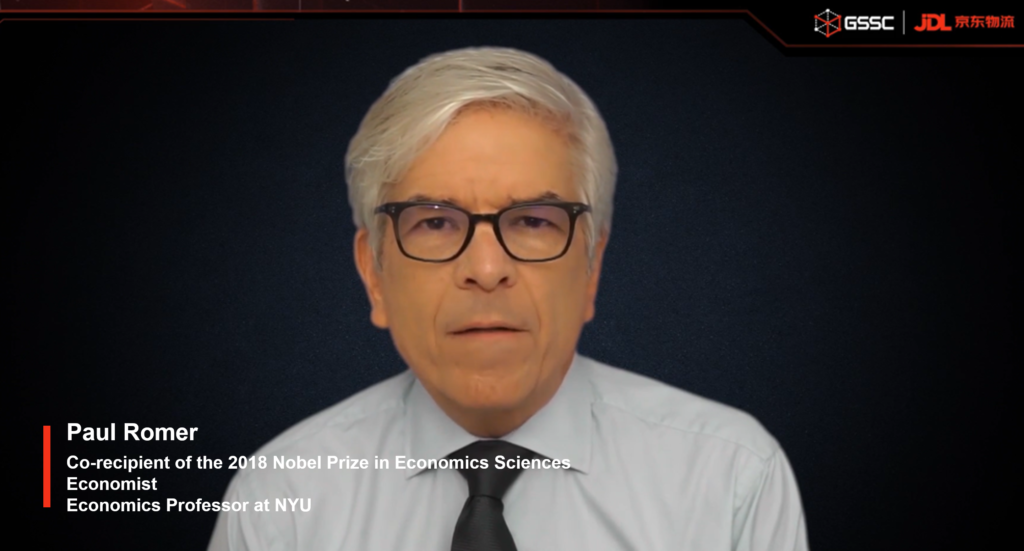

The rise in China’s supply chain system may ultimately result in a more robust global supply chain network, by pushing innovation and evolution that may not naturally have occurred in America’s more entrenched system, said Paul Romer, NYU economics professor and co-recipient of the 2018 Nobel Prize in Economics Sciences.

Speaking during JD’s Global Supply Smart Supply Chain Summit (GSSC) on October 22nd, Romer noted that the current friction between the two systems (and countries) is natural. “Nations rarely maintain their position at the cutting edge of innovation and growth and discovery,” he said. “And it’s important that new nations come along who can keep the process of growth and discovery moving. The incumbent, the former leader, never likes it when this happens. So, there will be some friction along the way.”

This kind of shift is healthy, whether within the global supply chain network or on a smaller level within industries, Romer said. If one enterprise maintains leadership within an industry over decades, that almost certainly will lead to stagnation and lack of innovation. The rise of new entities—and ideas—is essential to avoiding a “monoculture” of ideas, something the American system is now facing in its long-established supply chain, he said.

In China, JD.com is driving the kind of innovation that Romer spoke about. Today the company announced that it will put 100 autonomous delivery robots into operation in Jiangsu province’s Changsu city by the end of the year. JD will work with the city’s government to develop a smart city infrastructure to support the autonomous driving technology for delivery.

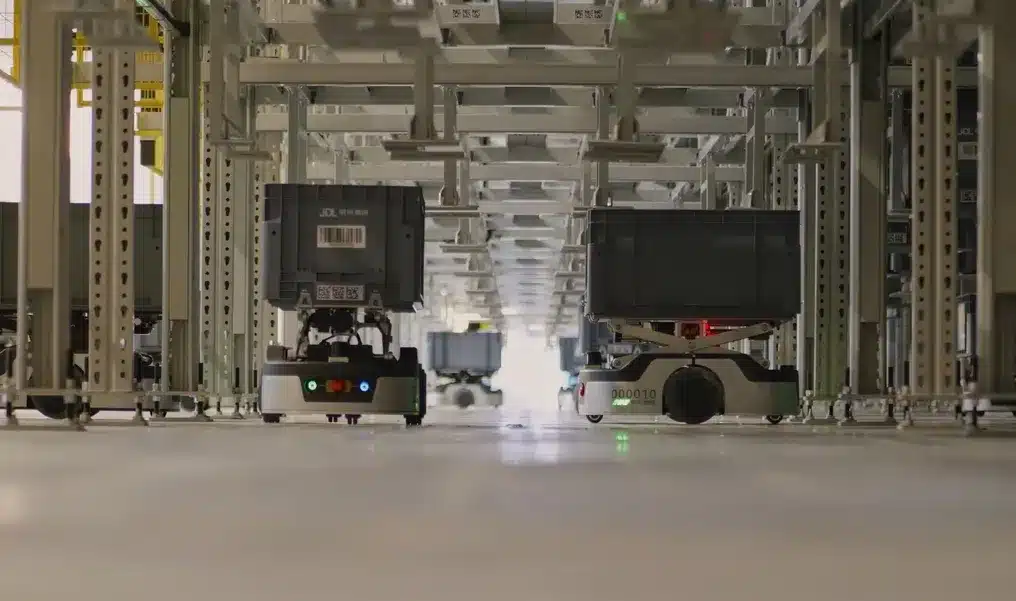

JD is also pushing forward the use of intelligent technologies in its warehouses. In 2017, JD launched the world’ s first fully automated B2C warehouse; today, 70 of JD’s warehouses implement automated technologies, including AGVs for picking up and sorting orders; and more. Additionally, twenty-eight of our Asia No. 1 fulfillment centers utilize 5G, integrating edge computing, big data, AI and SaaS.

Recently JD helped Japanese firm Rakuten, Inc., a global leader in Internet services, complete a successful demonstration of drone delivery beyond visual range. This marked the first time in Japan that a drone was used to deliver supplies in a mountainous region where the difference in altitude between takeoff and landing locations reached approximately 1600m. JD provided the drone and technology to achieve this maiden flight.

These kinds of innovations represent the progress that can be made by each individual entity that participates in the global supply chain, a point that Romer compared to a classic analogy posed by Adam Smith. In a pin factory, each individual is responsible for one particular task, refining and perfecting that task over time—and then that task becomes part of a chain of tasks, each perpetually improving to eventually form the strongest possible chain. Similarly, the global supply chain is made up of such individual entities, in the form of brands, manufacturers and enterprises like JD.

Ultimately small refinements and innovations by each link in the chain will drive evolution, Romer said. “Those ideas are ultimately much more important and have a bigger impact on our daily life then the kinds of things that get published in a scientific journal.

“The global supply chain is the modern reflection of the most important dynamic in economic life,” he added.

Romer’s comments came amidst the fifth GSSC summit, which is an annual event focused on logistics innovation and technology communication on a global scale, hosted by JD Logistics. Under this year’s theme of “Open Capabilities, Shared Growth”, the GSSC gathered the world’s leading experts in the industries of logistics, commerce, science and technology to discuss how to seize the opportunities provided by the macro environment and policy, with an aim to reshape the industrial supply chain and promote high-speed growth.

GSSC Series: JD Empowers Industries Through Supply Chain Solutions

GSSC Series: JD Empowers Industries Through Supply Chain Solutions