Nov 27, 2020|

In-Depth Report: JD’s CSO: Hit the Re-Start Button of Supply Chain

by Ella Kidron and Ling Cao

“What ability has gotten JD to where it is today, 10 years later?” asks Dr. Jon Liao, Chief Strategy Officer of JD.com. He addressed the audience during a keynote speech at the company’s 4th annual tech summit, JD Discovery (JDD), held on Nov. 25th in Beijing. The answer is JD’s unique supply chain infrastructure, which will enable JD to optimize cost, efficiency and experience across all industries.

Jon Liao, CSO of JD.com gives keynote at JDD

JD then and now

The world looks vastly different than it did ten years ago. Liao recalls Bill Gates’ well-known quote, “We always overestimate the change that will occur in the next two years and underestimate the change that will occur in the next ten.” From an external perspective, the consumer internet, which increased the efficiency of transactions, has become the industrial internet, increasing the efficiency of industry. Changing consumer habits, shopping scenarios and technologies continue to transform the retail industry. Livestreaming e-commerce, for example, has taken China by storm this year and is beginning to percolate into other markets. This general uncertainty has only caused JD’s commitment to supply chain to grow stronger.

Hu Hao, head of supply chain innovation at JD.com said in an interview, “Because retail is constantly changing, any scenario meant to serve customers must consider the notion of supply chain.” Supply chain is the number one consideration in ensuring a consistent experience.

In the same vein, the JD.com of 2009 was a 2,000-person company valued at US$250 million. Today, the company has more than 320,000 employees (according to Q3 financial results) and a market cap of US$130 billion. “In 2007, JD invested in supply chain, and this supply chain has become today’s JD,” explained Liao.

“In the past, when others were emphasizing platform and transaction efficiency, JD was doing industrial internet,” said Liao. “What we have been steadfastly committed to over the past ten years has become our most powerful infrastructure capability.”

Contributions of JD’s supply chain to society

JD Chairman and CEO Richard Liu’s “ten section” operating theory, is based on the idea that retail has ten components: creativity, design, R&D, manufacturing, pricing, marketing, transactions, warehousing, delivery and after sales. In 2007, Liu invested the first large sum of money he received into supply chain. The reason is he believed the first principle of retail revolved around three things: cost, efficiency and experience, where cost and efficiency represent supply chain and experience represents users. This is experience, which is visible. What is invisible, on the other hand, is the cost and efficiency of the supply chain. Of the ten sections, JD has focused on the last five sections, beginning with transactions, and expanding to warehousing, delivery, after sales and marketing.

JD is able to manage over five million SKUs, a process which involves a massive storage system, sorting center, tail-end service network and more, all with the purpose of supporting consumers all across China within 24 hours (JD is able to deliver 90% of first party retail orders same- or next-day). “The computational and intelligent capabilities behind the scenes [required to realize this] are hard to image. This type of infrastructure has become world-leading, and the service we provide has become standard [in the industry],” said Liao.

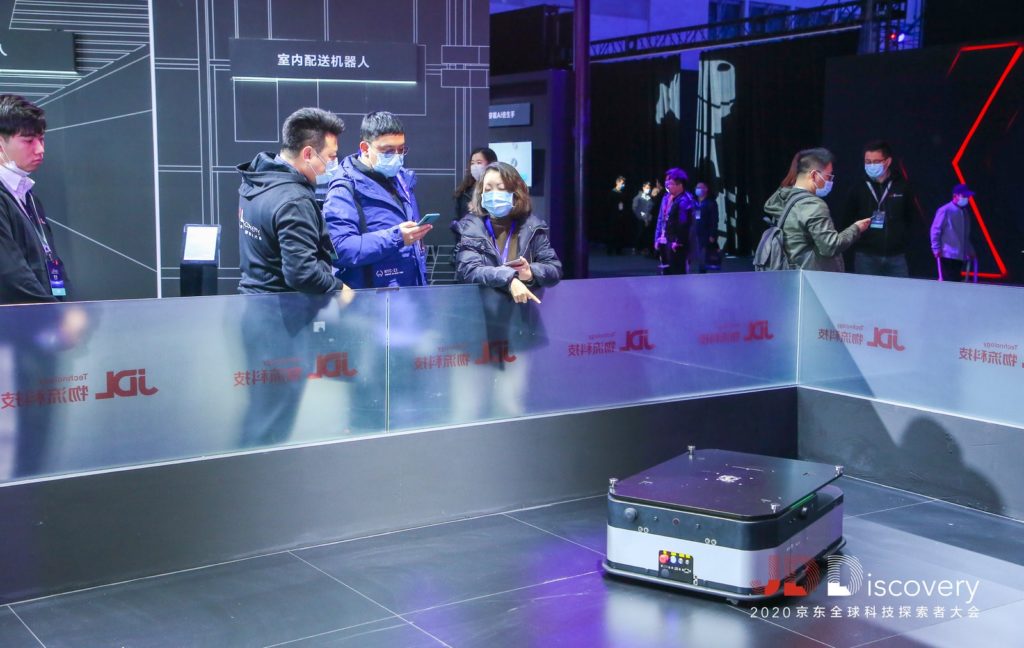

The JD Logistics booth at JDD

The infrastructure is predicated on JD’s technology abilities covering smart supply, smart logistics and smart consumption. JD’s supply chain efficiency has already made significant contributions in China. Liao explained that in 2007, when JD made its first investments into supply chain starting with its logistics network, logistics costs of China as a whole were 18.4% of GDP. Today, that figure is 14.7%, a drop of 4%. “If we compare today’s 14.7% with Europe and the US where the number is less than 10%, we see that we still have a huge amount of room to improve efficiency, which is why we need to build new infrastructure in the future.”

Next steps for supply chain development

Liao characterizes JD’s next steps in supply chain development with a 4D- principle. He said supply chain should be constructed around deep connectivity, deep data (including entire industry chain data), deep tech (blockchain, edge computing and other technologies which can take the supply chain to the next level) and deep intelligence.

Supply chain development should also consider how consumption is changing. As can be seen across industries, consumption is moving from general to precise and accurate – from a market of many to a market of one; from a batch of goods to a single product. “Looking at the future of retail, this means getting the right product to the right customer in the right place at the right time.” This customer can be an individual consumer, enterprise consumer or even a government client.

If the first half of retail was represented by digital and smart technology, then the second half is about using new technology across many vertical industry supply chains. What will this supply chain look like? According to Liao: 1) Wide: extended from merchandise- to service-related industries, including finance, healthcare and the auto aftermarket, 2) Deep: from the domestic supply chain to the overseas market, helping the domestic supply chain go abroad and vice versa, 3) Thick: from serving customers to serving customers and enterprise clients, 4) Long: from retail, logistics and post-sales to upstream parts of the supply chain including R&D, design and more, and 5) Virtual: making traditional supply chain infrastructure virtual through data and technology applications.

Building supply chain infrastructure with partners

At the Open Day for JD-Y (smart supply chain innovation) held on Nov. 26th in Beijing, Chen Lin, vice president of JD.com and head of JD’s ecosystem business, said that supply chain must have three characteristics: demand-driven; open and collaborative; and agile and responsive. He commented that even amidst uncertainty of COVID-19, perhaps the biggest uncertainty is user demand. Hau L. Lee, a Stanford professor and Chairman of the GSIC (the Global Supply Chain Innovation Center developed by JD and partners), explained that after 9/11, Zara started manufacturing clothes in more somber colors sensing this is what consumers demand. Today, with all of the technology and analysis tools, “every day is an opportunity to create a new product,” given that there are new consumer demands every day.

Chen Lin makes a speech during Y Open Day

An open approach is essential to meeting ever-changing consumer demand. Lin said, JD is strong sections 6-10 of retail, (marketing, transactions, warehousing, delivery and after sales) its brand partners are strong in the first five at the beginning of the product creation process (creativity, design, R&D, manufacturing, and pricing), further emphasizing the need for open collaboration.

JD already has evidence of successful supply chain collaboration with partners such as appliance manufacturer, Midea. Hu said: “In the collaboration between JD.com and home appliance company Midea, we optimize and collaborate on the forecasting, supply and demand, procurement, order execution and other processes, so as to make the supply chain more agile, easier to predict, and able to operate with more flexibility. In this case, both parties benefit in being able to perform better and optimize profit.” Kaishen Wang, head of the refrigerator e-commerce department at Midea, said: “After cooperating with JD, our inventory turnover days were reduced from 45 days at the most to only 28 days.”

At JDD, discussed how JD has reconstructed the medical supply chain to support daily needs. On the one hand, the efficiency of JD’s pharmaceutical supply chain has greatly improved, while connecting to the medical triage system. “Based on our internet healthcare platform, there are currently 80,000 doctors coming in contact with 120,000 consumers online each day.” JD’s supply chain is equipped with medical resources that enable people in rural areas to have access to the same quality of health care as top cities. JD’s “Family Doctor” service extends the supply chain from the commodity end to the medical services end. Behind it is a powerful medical technology and digital management platform.

Liao also discussed how JD could use its digital supply chain to reconstruct the PC supply chain. On the front end, JD’s big data and consumer insights indicate what type of display screen, processor and performance consumers are seeking. This information can be fed back to suppliers such as HP, and integrated organically with Intel, Microsoft, and others simultaneously. “In other words, from the first day of the product, we know very clearly which ones will [perform well]. We also know which kind of products we will need in Baoding and Chengdu, and when we will need them. From the very first day of production, we have a very accurate directional logic, which greatly reduces time to market.” The product’s design is also more accurate, improving the efficiency of the whole PC supply chain.

From empowering business to empowering society

“There’s no doubt that these next ten years and are the years of the industrial Internet.” Liao eyes three long term objectives for JD’s digital intelligent supply chain based on the industrial internet: 1) Empower the retail economy, covering 1.5 billion customers across the globe and nearly 10 million enterprises, 2) improve efficiency among industries and help clients reduce inventory turnover rate by 30% on average and lower the costs of society’s logistics costs to less than 10%, and 3) promote environmentally friendly programs. JD aims to achieve a 50% reduction in carbon emissions by 2030.

“In the future, every industry is worth doing again from scratch.” JD is developing the underlying supply chain infrastructure to enable partners across industries to hit that restart button. But the process has just begun. Liao quotes Winston Churchill, “Now is not the end. It is not even the beginning of the end. But the end of the beginning.”

Experts gathering at JDD

This Harbin tourism boom has also spurred a surge in sales of winter apparel. JD.com’s data indicates a rapid growth in the sales of warm clothing items such as down jackets, snow boots, and thermal underwear between January 1st and 7th. The sales growth is especially pronounced in southern provinces and cities such as Jiangsu, Zhejiang, Guangdong, Sichuan, and Shanghai. Notably, tall snow boots registered a 206% year-on-year increase in transactions, while padded cotton caps and thickened long down jackets soared by 158% and 134%, respectively. Beyond clothing, travel gear has also seen a considerable uptick, with a 98% year-on-year growth in transactions for large suitcases and travel backpacks in these southern regions.

This Harbin tourism boom has also spurred a surge in sales of winter apparel. JD.com’s data indicates a rapid growth in the sales of warm clothing items such as down jackets, snow boots, and thermal underwear between January 1st and 7th. The sales growth is especially pronounced in southern provinces and cities such as Jiangsu, Zhejiang, Guangdong, Sichuan, and Shanghai. Notably, tall snow boots registered a 206% year-on-year increase in transactions, while padded cotton caps and thickened long down jackets soared by 158% and 134%, respectively. Beyond clothing, travel gear has also seen a considerable uptick, with a 98% year-on-year growth in transactions for large suitcases and travel backpacks in these southern regions.

Italian Brand POLINA ELVIDO Landed on JD

Italian Brand POLINA ELVIDO Landed on JD