Jan 13, 2021|

Digest: JD’s C2M is Gaining Speed in China’s “Factory Revolution”

by Vivian Yang

China Entrepreneur Magazine published its first cover story in 2021 on January 5th, focusing on the topic of Chinese factories’ “C2M” movement, and recognizing that the Customer-to-Manufacturer model is becoming an important force in driving the digital transformation of factories, with COVID-19 being an accelerator of this trend.

The article, having been widely reposted and discussed on multiple media platforms, argued that e-commerce companies like JD.com and other main players on the market which have accumulated years of data, traffic, consumer’s insights and marketing means are in a race to use C2M to engage factories in China and transform them for flexible manufacturing.

“A factory revolution is happening,” said Zhenhong He, president of China Entrepreneur Magazine. “E-commerce companies, manufacturing enterprises and tech companies are the three main forces amid the race to grab factory resources in China right now.”

Behind the race for factories is a RMB 40 trillion yuan available market. Data of the National Bureau of Statistics shows that China’s total economic output in 2019 was close to RMB 100 trillion yuan, in which the industrial sector contributed 39%, or near RMB 40 trillion yuan. However, internet technologies have a very low penetration rate so far in this market, presenting an enormous opportunity for a “factory revolution”.

A study on innovation conducted by Clayton Christensen (1952-2020), the late Harvard Business School professor and the founder of the theory of “disruptive innovation” shows that only 5% of new products developed by most companies will achieve market success, while the R&D expenditures on new products can take up 50% of these companies’ total budget.

The 5% vs 50% finding resonated strongly with Dr. Bowen Zhou, chair of the JD Technology Committee: “If a company does not develop new products, it will lose market and die; but if they go for innovation, the chance for success is merely 5%. This is the deepest pain point of innovation.”

According to Zhou, JD’s technologies will help its partners to shorten more than 80% of the time to market for their new C2M products.

“We aim to build a C2M technology that is fully powered by AI, including using AI to understand customers’ potential demands, simulating users’ reactions through a neural network, and simulating the evolution of the C2M products through another neural network,” explained Zhou.

In the eyes of Dr. Jianwen Liao, Chief Strategy Officer of JD.com, C2M is the ultimate model of a mature supply chain. “Changes are happening every year in the retail industry, but the supply chain will remain unchanged. Looking across the world, most of the leading retail companies all have strong abilities in integrating the supply chain.”

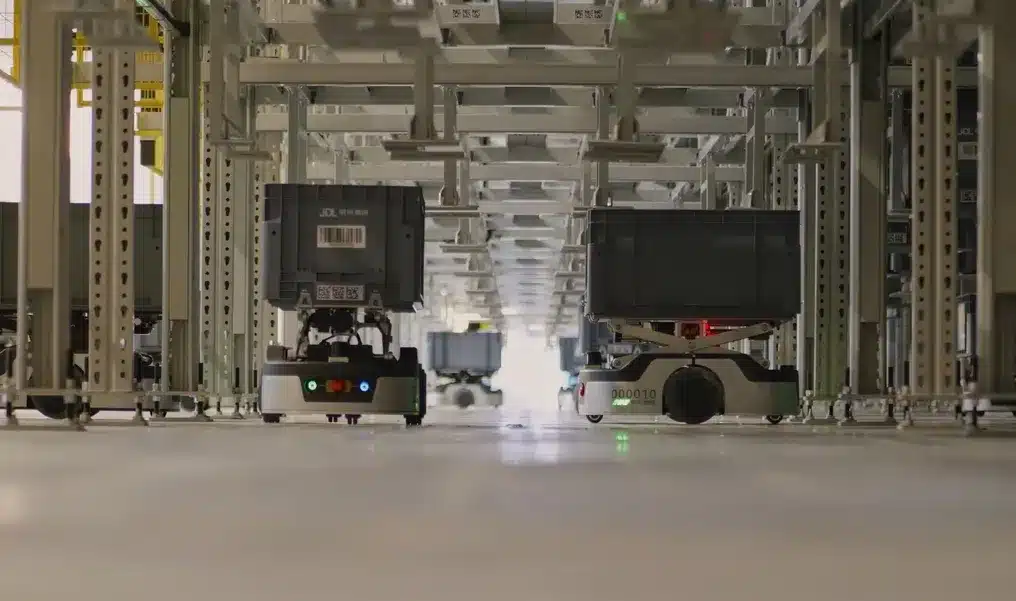

Today, JD Retail manages more than 5 million SKUs and operates over 700 warehouses, with inventory turnover rate as low as 34 days, a remarkable supply chain efficiency given its scale, and the rate continues to improve.

The report noted two characteristics of C2M supply chain innovations: one is to organize products’ design and manufacturing based on consumers’ demands; the other is to minimize the intermediaries between manufacturers and end users. Zhou said that JD keeps leveraging its technologies in AI, 5G, IoT, Cloud and more to build intelligent C2M factories which can effectively connect the whole chain of production, circulation and services.

JD launched its private label brand Jing Zao in collaboration with partnered manufacturers in 2018, followed by a series of initiatives in 2019 including detailed guidance for brand partners on making products with reverse customization, customized C2M services for customers’ clothes orders, a dedicated C2M online channel for direct-from-factory products and more.

Among the total of 6.7 million manufacturing factories cross China, their level of digitalization is less than 20% at present. With the growth of their digitalization, more small and medium-sized factories will be able to connect with greater market demands, which will in turn create more opportunities for the development C2M model, the report said.

How JD Medicine Procurement Helps SME Drug Stores Leapfrog

How JD Medicine Procurement Helps SME Drug Stores Leapfrog