Oct 23, 2020|

GSSC Series: Cars, Down Jackets, Crabs, And Supply Chain in China

by Vivian Yang

Logistics is often considered a behind-the-scene industry, but this year it has been brought into the spotlight amid the disruption of the Covid-19. “China’s logistics industry is facing a challenge that has never been seen before, but the challenge is also creating an opportunity for the revolution of productions and businesses,” said Xiaobo Wu, a well-known Chinese business writer, at the Global Smart Supply Chain Summit held online on Oct. 22nd.

As a writer who spends quality of time studying companies and new business trends in China, Wu shared three stories that reveal how supply chain capacity can reshape China’s manufacture industry and the way people do business.

The first story is about the Wuhan-based Honda car assembly plant. Its quick production recovery from the coronavirus impact has been widely reported in the media. The plant was shut down on January 23rd when the city lockdown started. After the height of the pandemic had passed, it reopened with twenty cars rolling off its production line on March 11th.

The plant’s director told Wu that there are more than 600 processes and 10,000 components supplied from different places to produce the cars. Their assembly line would not have been restarted without a strong support provided by supply chain and logistics services.

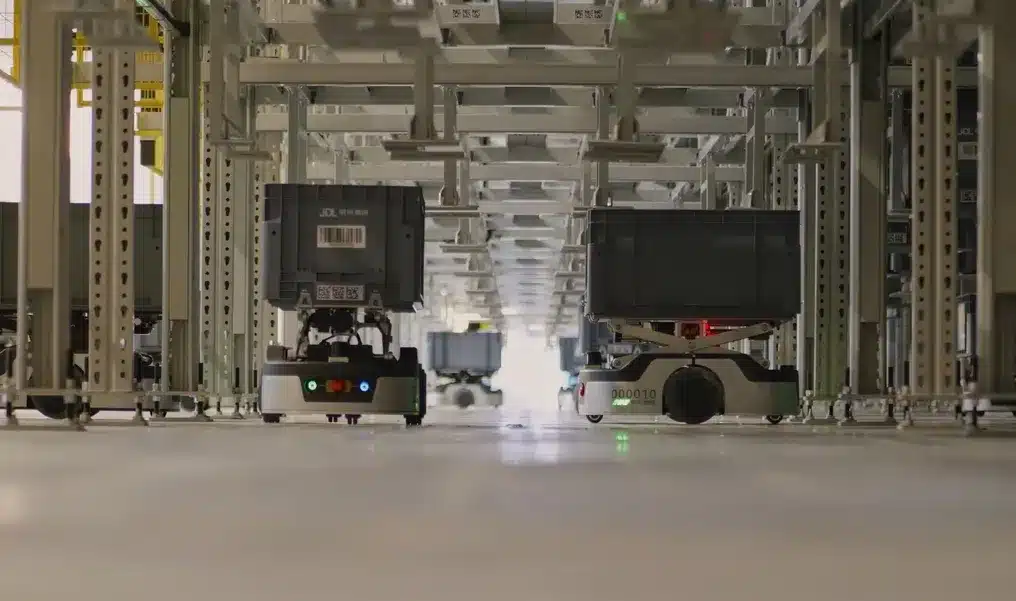

The second example is China’s famous down jackets manufacturer BOSIDENG, which produces over 3 million jackets a year and delivers orders to its customers across China within 24 hours. Even for bespoke items, like jackets customized by size or style according to customer’s personal preferences, customers can also receive their tailor-made products within a day. How can they do this? Wu visited BOSIDENG and found that its warehouses are seamlessly connected with JD’s warehouses. This e-commerce-driven warehouse integration has greatly helped manufacturers improve their fulfillment efficiency and production capacity for more customized products.

The third story is about the sales of hairy crabs from Yangcheng Lake in eastern China’s Jiangsu province, the premiere origin of the popular autumn delicacy. Because it was previously very difficult and costly to deliver live crabs, as of three or four years ago most crabs were consumed within this region, with a transaction volume of less than RMB 20 billion yuan a year. But nowadays, thanks to logistics companies’ cold chain delivery services via flights and hi-speed trains, hairy crabs from the famous lake can be shipped to over 1,000 cities across China within 24 hours, activating a market that is now worth more than RMB 100 billion yuan a year.

Watch the replay of Xiaobo Wu’s speech online

In his speech, Wu identified four areas of remarkable progress in China’s logistics industry in the past few years. First, internet-based e-commerce has triggered the explosive growth of logistics services. Second, traditional manufacturers are propelled to upgrade or even re-build their production lines to meet the demand of continued e-commerce growth. Third, an increasing number of integrated warehousing and distribution centers are built to enhance logistics efficiency. On this point, JD’s self-built integrated fulfillment centers have become an economic moat that distinguishes itself from other competitors. Fourth, highly efficient last-mile delivery networks are ready in place across the country sustained by 4.5 million couriers on a daily basis.

“The revolutionary changes that have taken place in China’s logistics sector are the result of joint efforts by many people, including entrepreneurs in the manufacturing, transportation and other sectors, as well as those young couriers running on the road for the last-mile delivery services,” Wu said. “All of these contributed to China’s unique logistics landscape. Any broken link in the chain will hinder success.”

Wu also touched upon the role of technologies such as AI, 5G, big data, self-driving vehicles and more in driving logistics development. With the application of these technologies in recent years, JD Logistics’ networks are now able to cover all the administrative counties in China now, including more than 20,000 small townships and over 99% of the total national population, with 90% of orders delivered within 24 hours.

“At my home in Hangzhou city, it only takes 12 hours,” Wu said. “When I place an order on JD in the morning, the parcel will arrive around 4 to 5 pm at my doorstep in the afternoon of the same day. China has the most imaginative environment in the world for the revolution of the logistics industry.”

GSSC summit is an annual event held by JD Logistics that focuses on logistics innovation and technology communication on a global scale. Under this year’s theme of “Open Capabilities, Shared Growth”, the GSSC gathered the world’s leading experts in the industries of logistics, commerce, science and technology to discuss how to seize the opportunities provided by the macro environment and policy, with an aim to reshape the industrial supply chain and promote high-speed growth.

(vivian.yang@jd.com)

Sales of JD’s Private Label Products Surge amid Singles Day Promotion

Sales of JD’s Private Label Products Surge amid Singles Day Promotion