Nov 23, 2020|

HBS Students Take a Virtual Trip to JD.com

by Ella Kidron

Harvard Business School (HBS) students took a virtual field trip to JD.com in Beijing on Nov. 20th to hear from Natasha Li, director of supply chain planning products in the value supply chain (VSC) division at JD Logistics (JDL). In a session facilitated by HBS professors Willy Shih and Feng Zhu, Li, a veteran in the supply chain industry with over 15 years of experience, shared on the role of intelligent supply chain in JD’s business as well as the services it has opened up to external partners. Over 100 HBS students from all over the world participated in the lively hour-long discussion.

Natasha Li

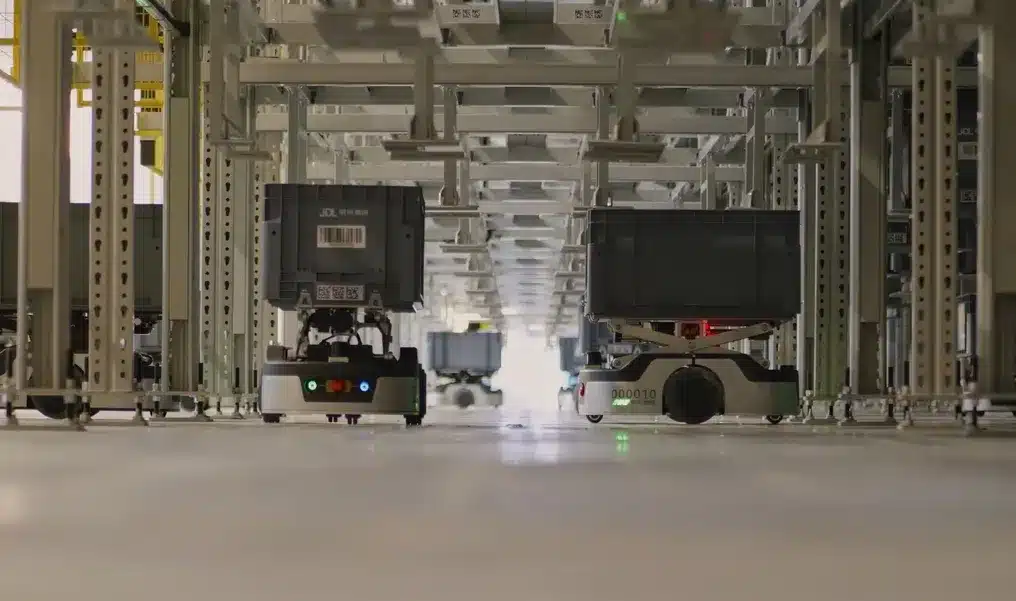

“JDL is a supply chain platform based on the strategy of ‘technology-driven, leading the world’s efficient circulation and sustainable development’,” explained Li. She added: “Automation and robotics constitute the foundation of JDL’s intelligent supply chain.” This advanced technology is applied in JD’s automated warehouses as well as smart delivery stations and autonomous delivery vehicles, among many other use cases.

Natasha Li (Weijing Li) and HBS professors Willy Shih and Feng Zhu

Li cited JD’s cooperation with global conglomerate Nestlé on a large-scale smart storage and distribution center as an example. She explained that, using JD Logistics’ superior operational capabilities and technology advancements in supply chain management, the distribution center has is able to identify specific products, recognize their locations and use advanced intelligence to visualize and control the migrations or infiltrations of loads between different provinces.

Another critical application of technology is behind the scenes and heavily reliant on an intelligent solutions system. “The application of smart technology like AI has greatly improved the efficiency of our supply chain,” said Li. She explained that, through AI, JD is able to efficiently and orderly manage over six million SKUs maintaining an industry-leading 34.3 inventory turnover days, all while delivering over 90% of first party retail orders in just 24 hours.

JDL is opening up its capabilities to other companies as a service, and is becoming a platform.

JDL’s value supply chain (VSC) empowers various industries with supply chain technology. In the discussion, Li shared one example of Company W, an automobile company that is a beneficiary of JD’s VSC. She explained that the company needs to manage tens of thousands of after-sales spare parts. Previously, the company was heavily reliant on a very rudimentary Excel-based system, requiring huge amounts of manual labor and guess work, resulting in the company facing high inventory and logistics costs, no ability to conduct sales forecasts, mismatched capability planning, and inharmonious collaboration between suppliers and automobile company.

JDL’s VSC team used JD’s technology to set up a smart decision making engine, an algorithms platform covering AI, optimization and forecasting, and a simulation center. Through the “Jinghui” digital supply chain platform product, JD helped Company W realize systematization of supplier – RDC (regional distribution center) – “4S” stores, and set up demand driven forecasting, big data insights-driven decision making and more. Implementing the Jinghui system reduced the supply hierarchy and enabled the company to achieve network-wide collaboration. As a result, customer service improved 10% and inventory turnover days were reduced from 50-80 to 30-35.

Agility is one of the core advantages of JD’s supply chain and also the secret to its peak performance, as well as that of its partners. “The adoption of big data application and AI algorithms makes all aspects of the supply chain, such as demand forecasting, inventory allocation, and operations scheduling more accurate, efficient and perceptive to change.”

This is something that was made clear at the height of the COVID-19 outbreak in China. “During the pandemic, the agility of JD’s supply chain made it possible for the company to quickly respond to emergencies and ensure the recovery of production capabilities.” For example, JDL quickly increased inventory in its various front warehouses based on consumption big data to make sure that goods were placed as close to customers and could be delivered as soon as possible. Separately, at the end of December 2019, before the official COVID-19 outbreak was called, JDL’s monitoring system flagged a significant increase in mask sales in Wuhan, Hubei province, and immediately prepared 70,000 masks for its courier in the city and carried out replenishment and internal alerts.

The session concluded with an interactive Q&A in which students asked about a wide range of topics including returns, sustainability and more. On returns, Li explained that efficient logistics for returns is an important aspect of JD’s customer service value proposition. She explained: When it is easy to make returns, it helps customers feel more comfortable about making decisions to place orders more quickly because they know that if something doesn’t fit or isn’t the right color, they can return it hassle-free. As for sustainability, Li mentioned that JD plans to reduce carbon emissions by 50% by 2030 as part of a long-term commitment to increasing sustainability in the supply chain.

JD Tops the Ranking of Green Packaging Actions in China’s Express Industry

JD Tops the Ranking of Green Packaging Actions in China’s Express Industry