Apr 23, 2020|

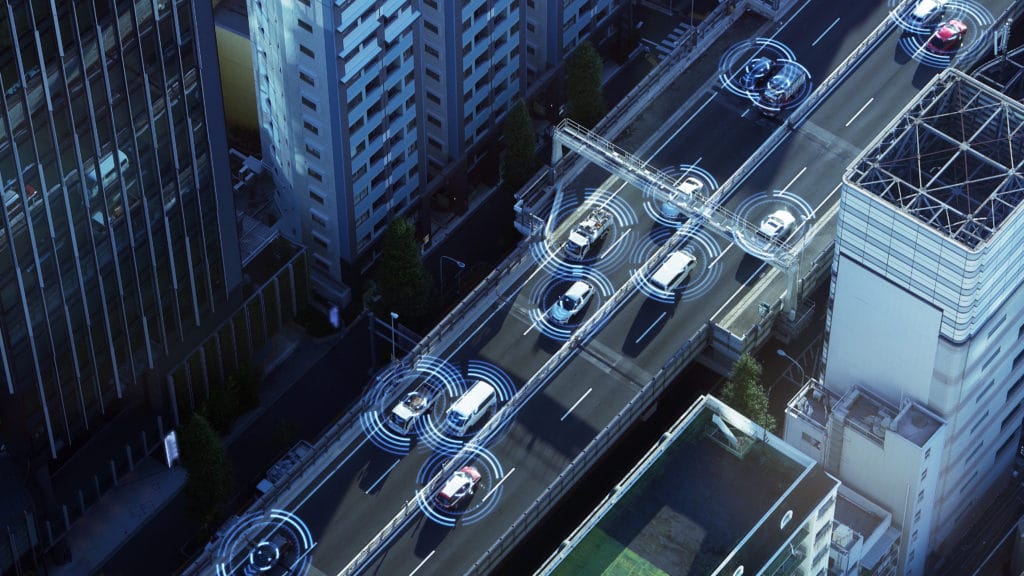

In-depth Report: When Big Data and IoT Meet JD’s Logistics

by Ling Cao

When the COVID-19 epidemic broke out, JD rapidly arranged its logistics network to transport medical supplies and daily necessities. The company also deployed drones and autonomous delivery robots to help on the frontlines. Behind the scenes, JD’s technology – a combination of big data and algorithms – plays an essential role enabling a highly efficient logistics network that is flexible enough to be applied for normal and emergency conditions. So, how is it done? What is the next step for technology development in the future? The secret may unveil itself in three aspects: Warehousing, transportation and delivery.

Warehousing

Looking from the top network design level, based on big data and algorithms, JD will design its fulfillment network layout to make sure it puts products closest to its customers. JD has a self-developed, integrated warehousing system, which can integrate all the software and hardware systems together, making sure they can work as efficiently as possible. Based on operations optimization algorithms, logistics simulation technology (which can simulate real scenarios on a platform) and machine learning, JD can achieve smart warehousing throughout the whole supply chain, including smart forecast, smart inventory management, smart scheduling and operations. To make it more user-friendly, all operations can be managed through both PC and mobile terminals.

Set optimizing the sorting process as an example. JD will deal with several million stock keeping units, or SKU, every day. How can the company make sure the sorting process is accurate and fast? Since 2007 when JD started to build its logistics network, the sorting process has gone from purely using manpower to being handled automatically by multiple machines. For example, JD developed an automated guided vehicle which can transport an entire shelf to warehouse workers, so that workers only need to scan products from the shelves. Previously they would need to walk all around the warehouse to pick up goods. The automated system can simultaneously improve both sorting accuracy and the efficiency.

Another innovation for the sorting center is that JD’s self-developed Internet of Things, or IoT-based plastic cargo bags (a bag used to collect multiple parcels in one place). Previously, due to the large size and volume of the bag and its content, as well as its irregular shape, the barcode on the bag will hardly be recognized by laser scanning devices or image recognition devices. But IoT based technology can help the bags automatically be recognized and sorted, with a sorting accuracy of 99.99%, improving operational efficiency by more than five times.

Transportation

It’s easier to do route optimization in a warehouse since the scenario involves a fixed space and is in a relatively unchanged environment. If we are talking about transportation and delivery on real roads, there are higher requirement for route optimization as the solution needs to consider the specific conditions of a particular road.

Powered by AI technology and big data, JD can achieve dynamic transportation route planning, which can connect the entire sorting process, from warehouse, to delivery stations nationwide, and to couriers ultimately. The whole process will be fast and organized. For example, the system can recommend the transportation route and frequency based on analysis. Eventually, it can reduce unnecessary touch points in the transportation process, improving vehicle utilization rate by over 40%.

The COVID-19 outbreak put pressure on Wuhan’s supply chain. JD tested the risk through its “digital twin model”, which can simulate and forecast the real conditions, in order to better evaluate the impact on road closure of dozens of main roads in and out of Wuhan, as well as the indirect impact on hundreds of routes nationwide. Using the technology, JD made the emergency adjustment plan in a timely manner. For example, JD adjusted a new route planning solution in just several minutes, ensuring needed supplies reach to Wuhan as soon as possible, whereas other items that don’t need to be transferred via Wuhan can be detoured from other cities.

Delivery

For last mile delivery, one important consideration is that how to better set the delivery frequency for each delivery station in order to make sure orders can be achieved same day or next day, especially when there are multiple delivery requirements from customers, such as scheduled delivery.

JD’s technology combined traditional Operations Research (OR) with big data from couriers’ existing delivery routes, and enhanced the efficiency and accuracy from the strategy level. In this way, JD can work out the best margins for cost and efficiency. Set JD’s Yizhuang smart delivery station in Beijing as an example. There will normally be two time slots, one in early morning, and another in the early afternoon during which trucks with parcels will arrive from warehouses. Couriers only need to deliver parcels to customers two times a day. In this way, the station can meet JD’s promise of delivery speed while being cost effective.

The coordination of warehousing, transportation and delivery also guarantees JD can prepare and go through each big sales promotion without a hitch.

Set last year’s Singles Day (November 11th) promotions as an example. During the promotion, 92% of first party orders were delivered same- or next-day, despite the mass number of orders from JD Retail and over 200,000 third party merchants (either external or on JD). The success is mostly because of JD’s accurate forecasting. The technology is based on a forecasting platform, which will mainly focus on three forecasting services, namely JD’s in-house inventory forecast, JD’s key accounts’ logistics order forecast, and importantly, JD’s logistics forecast middle platform, which can quickly respond to support all forecast scenarios.

Based on how many orders JD may deliver during a big promotion, JD will identify and allocate enough manpower, vehicles and other resources in advance to support the entire supply chain, ensuring a consistent customer experience even during peak times.

More scenarios

Beyond logistics, JD’s technology applied in logistics can also serve as a reference for other industries, such as leveraging machine learning for equipment fault prediction, which can be applied to other industrial device platforms. Big data and IoT can help other industries, such as smart home and smart cities industries, explore and innovate.

Future prospects

Looking ahead, Jianqiang Yu, R&D development head of JD Logistics shares that the future trend for logistics providers like JD is making every single technology flexible, like building blocks, so that it can serve more partners beyond its platform, in addition to its own business.” He used a metaphor to further explain, “For JD Logistics, when building the architecture of the underlying data, it is like building a house, we prefer to use bricks one by one, rather than a fixed frame, so that we can easily make adjustments.”

Jianqiang Yu, R&D development head of JD Logistics

This is also a time when 5G technology is developing. Logistics will be the best scenario to apply 5G and IoT technology. JD is leading in the application of these technologies in the industry by launching its first 5G powered logistics park in Beijing ,where IoT devices can achieve functionality which would hardly possible via a 4G or Wi-Fi network. For instance, using image recognition technology to monitor and alert for risk within a park to improve operation safety.

JD has been investing and researching IoT devices and systems for usage in its logistics network since 2016, and deployed IoT devices in transportation, cold chain monitoring and within its logistics parks. JD has long led the application of IoT and 5G in the industry.

JD has long been investing in technology development, with its R&D department has more than18,000 personnel. In 2019, the company filed 3,651 patents application with China National Intellectual Property Administration.

Wenming Zhe, chief architect and head of the 5G applications program at JD Logistics said, “5G and IoT enable us to realize the connection of all things. Based on Big Data, AI and robotics ensures continuous improvements in the logistics industry in terms of quality and efficiency. Smart logistics which is characterized by ubiquitous connection, digitization and intelligence, is becoming the driving force of China’s logistics transformation.”

This Harbin tourism boom has also spurred a surge in sales of winter apparel. JD.com’s data indicates a rapid growth in the sales of warm clothing items such as down jackets, snow boots, and thermal underwear between January 1st and 7th. The sales growth is especially pronounced in southern provinces and cities such as Jiangsu, Zhejiang, Guangdong, Sichuan, and Shanghai. Notably, tall snow boots registered a 206% year-on-year increase in transactions, while padded cotton caps and thickened long down jackets soared by 158% and 134%, respectively. Beyond clothing, travel gear has also seen a considerable uptick, with a 98% year-on-year growth in transactions for large suitcases and travel backpacks in these southern regions.

This Harbin tourism boom has also spurred a surge in sales of winter apparel. JD.com’s data indicates a rapid growth in the sales of warm clothing items such as down jackets, snow boots, and thermal underwear between January 1st and 7th. The sales growth is especially pronounced in southern provinces and cities such as Jiangsu, Zhejiang, Guangdong, Sichuan, and Shanghai. Notably, tall snow boots registered a 206% year-on-year increase in transactions, while padded cotton caps and thickened long down jackets soared by 158% and 134%, respectively. Beyond clothing, travel gear has also seen a considerable uptick, with a 98% year-on-year growth in transactions for large suitcases and travel backpacks in these southern regions. JD.com Provides Aid to Fight COVID-19 in South East Asia

JD.com Provides Aid to Fight COVID-19 in South East Asia