Mar 31, 2022| JD Logistics

JD.com Utilizes Robots in Shanghai for Contactless Delivery

by Yuchuan Wang

As the current COVID-19 outbreak in Shanghai grows, JD Logistics has launched its autonomous delivery robots in the city’s Pudong New Area to provide contactless last mile delivery for certain locked down neighborhoods.

The robot applied in Shanghai can load up to 100 kilograms of goods and drive 80 kilograms per charge. With AI technology and multiple sensors, the robot can recognize, avoid obstacles, and plan its route to the destination.

Since 2020, JD has deployed its autonomous delivery vehicles for COVID-19 relief in Wuhan, Shijiazhuang, Guangzhou, Beijing, Tianjin, Shenzhen and now Shanghai. In Wuhan, the robots traveled over 6,800 kilometers and delivered more than 13,000 packages during the peak of the pandemic in early 2020. “Big White”, one of the robots used in Wuhan, is now a permanent collection of the National Museum of China in Beijing.

JD.com debuted its first autonomous delivery vehicle in 2016 and revealed the Level-4 autonomous driving robot in 2019, becoming the world’s first company to apply Level-4 autonomous driving technology on public roads without any human interaction.

So far, the company has applied nearly 400 autonomous delivery vehicles in more than 25 cities in China, meeting the delivery needs in scenarios such as residential compounds, commercial centers, business parks, hotels, university campuses, supermarkets and more.

Jan 28, 2026| JD Logistics

From Fixed Capacity to Elastic Fulfillment: How JINGDONG Logistics’ LangzuTech Goods-to-Person System Redefines Smart Warehousing

- Modular, zone-based deployment allows warehouses to scale outputup or down with demand, reshaping fulfillment cost structures.

- Goods-to-person design leverages up to 12 meters of clear height, significantly increasing storage density and reducing warehousing cost per unit.

- Successfully deployed across apparel, pharmaceuticals, electronics, FMCG, and full-category warehouses with complex order profiles.

As e-commerce and omnichannel retail continue to evolve globally, logistics and supply chain operators are facing unprecedented operational complexity. Rapid SKU expansion, frequent assortment changes, and extreme order volatility, particularly during peak sales events, are placing growing pressure on traditional warehouse models built around manual labor and fixed capacity.

To address these challenges, JINGDONG Logistics has developed the LangzuTech Tote Handling, a Goods-to-Person (G2P) system.

An Integrated Goods-to-Person Architecture Built for Density and Accuracy

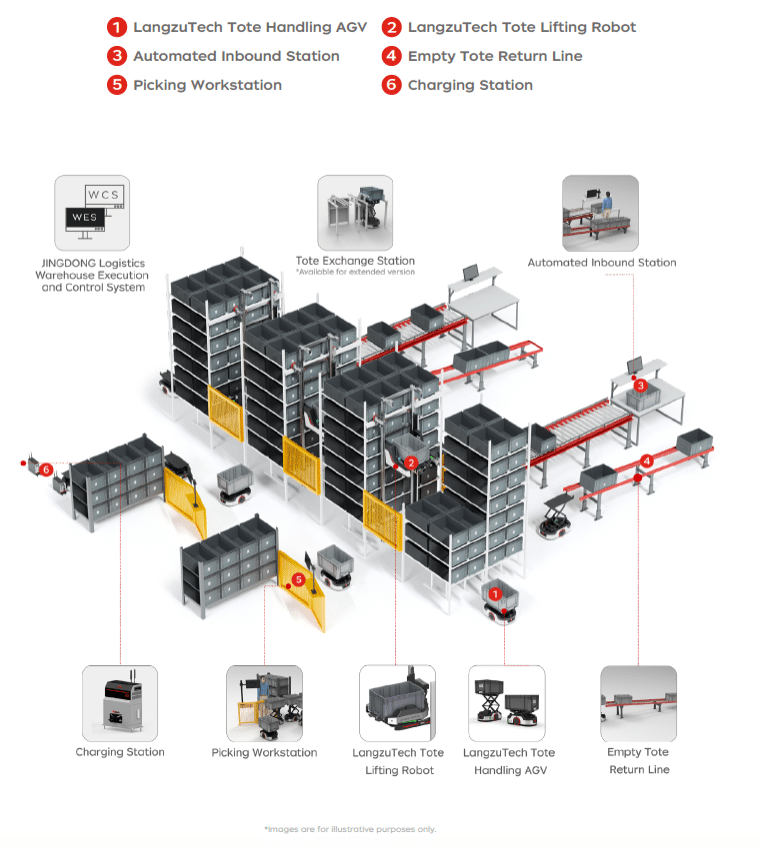

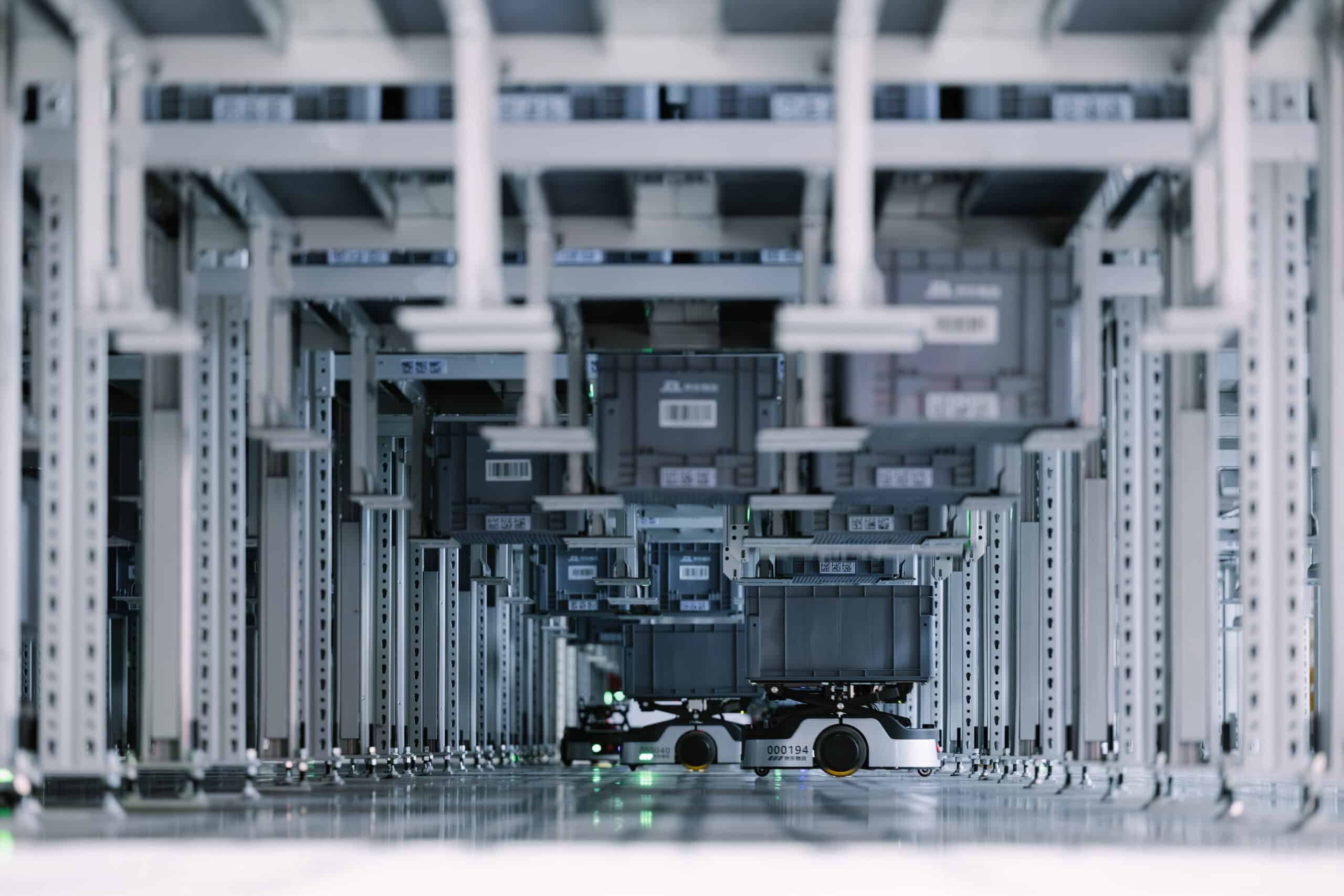

LangzuTech Tote Handling System is a fully integrated G2P solution that combines tote-handling AGVs, lifting robots, high-density three-dimensional racking systems, automated inbound and picking workstations, empty tote return lines, and centralized charging stations into a closed-loop operational flow.

Through intelligent spatial reconfiguration, the system maximizes the use of a clear height under 12 meters, enabling high-density storage that significantly increases space efficiency and lowers unit warehousing costs. Unlike traditional warehouses that rely on strict category-based zoning, it supports multi-SKU, multi-category storage within a single tote, minimizing consolidation and improving order assembly efficiency in mixed-order environments, while fully leveraging warehousing space.

Modular Deployment for Faster Time to Value

Unlike conventional automated warehouses that require large upfront investment and rigid capacity planning, LangzuTech Tote Handling System adopts a modular, building-block design. Warehouses can deploy the system by zone, implement it in phases, and scale capacity by flexibly adding or redeploying robots and workstations as demand fluctuates.

This allows operators to increase investment as their business grows. As a result, automation upgrades integrate smoothly into live operations, minimizing disruption while accelerating return on investment.

By shifting from labor-intensive, fixed-capacity models to a more agile, technology-driven framework, JINGDONG Logistics fundamentally reshapes the cost structure of fulfillment operations and lowers the entry barrier to intelligent warehousing for businesses of various sizes.

Proven Across Complex, Multi-Category and Regulated Environments

The solution has been successfully deployed across a wide range of industries, including apparel, e-commerce, pharmaceuticals, consumer electronics (3C), FMCG, and beauty.

In large-scale apparel fulfillment centers, where rapid onboarding of new SKUs and fast shelving are critical, it enables five- to sixfold improvements in inbound shelving efficiency without expanding warehouse footprint. In one high-volume apparel operation, hundreds of robots operate collaboratively across dense storage aisles and multiple workstations, supporting daily outbound peaks of over 30,000 orders while significantly improving fulfillment speed and stability.

In pharmaceutical applications, LangzuTech Tote Handling System delivers both efficiency and compliance. Each product is assigned a unique traceability code when it arrives, enabling end-to-end inventory visibility. The system automatically manages storage rules for cold-chain, light-sensitive, and regulated products, while continuously monitoring temperature and humidity. Near-expiry inventory triggers automated alerts, eliminating the need for manual inspections. By leveraging high-density storage and robot-driven handling, a pharmaceutical warehouse using the solution has achieved:

- Up to 4× storage density on the same footprint

- 99% picking accuracy

- Up to50% reduction in per-order handling costs

Order consolidation across multiple downstream outlets further shortens outbound lead times and strengthens overall supply chain responsiveness. In pharmaceutical operations in China, a LangzuTech-powered warehouse feeds hundreds of downstream retail pharmacies in the Beijing region. Without having to expand warehouse footprint, the overall processing capacity has increased by approximately 600%, compared with pre-automation operations.

LangzuTech Tote Handling Solution has now entered a phase of large-scale replication and deployment, supporting JINGDONG Logistics’ broader vision of building efficient, resilient, and sustainable supply chains worldwide.

As JINGDONG Logistics continues to expand its global warehouse network, which now includes more than 130 overseas, bonded and direct mail facilities worldwide, the LangzuTech solutions provide a standardized, yet flexible automation foundation that can be adapted to diverse regulatory, operational, and industry environments.

Dec 17, 2025| ESG, JD Logistics, JD Retail

JD.com’s Green Stream Initiative Selected as 2025 Sustainable Brand Exemplar; Among First Signatories to Geneva Visionary Initiative

JD.com is proud to announce that our flagship sustainability program, the Green Stream Initiative, has been selected as 2025 Sustainable Brand Exemplar at the “Building Sustainable Brands” Visionary Initiative, also known as the Geneva Visionary Initiative.

The honor was announced on December 15th at the United Nations Environment Programme (UNEP) global headquarters in Nairobi, Kenya, which draws leaders from the public and private sector to advance sustainable business practices.

The event was co-organized by UNEP, its One Planet Network, the China Association for Standardization, the Sustainable Business and Branding Working Committee, and the Sustainable Business Leaders Forum. The 2025 case collection spotlights leading examples where sustainability is seamlessly integrated into brand value and core strategy.

As one of the inaugural signatories of the Geneva Visionary Initiative in September 2025, JD.com stands alongside other large companies in illustrating the real-world impact of the Initiative’s five-dimensional framework, which fully integrates sustainability principles into business operations and brand value creation, covering strategy, business systems, products, technology, and branding.

Alison Gray Cairns, Head of UNEP’s Private Sector Unit, commended the visionary ambition of the selected projects and highlighted the innovative ways Chinese enterprises are creating value.

Zhang Xiuchun, Secretary-General of the China Association for Standardization, emphasized that unveiling these cases in Kenya represents a key milestone, shifting the Geneva Visionary Initiative from conceptual agreement to practical, actionable steps that strengthen global competitiveness through responsibility.

Spotlight on Ocean Box Partners

Central to JD.com’s recognition is Ocean Box Partners, a flagship project under the Green Stream Initiative initiated by JINGDONG Logistics, the company’s logistics arm. Building on JINGDONG Logistics’ mangrove restoration efforts that began in 2024, this second-phase project, now renamed Ocean Box Partners and often referred to as “Mangrove Ecosystem Project 2.0”, expands mangrove ecosystems in Hengqin National Wetland Park. These vital blue carbon habitats excel at carbon storage and coastal protection.

Launched on International Day for Biological Diversity (May 22, 2025), it continues to be led by JINGDONG Logistics in partnerships with the One Planet Nature Foundation and guidance from organizations such as the Hengqin-Macau Cooperation Zone, China Express Association, and World Wide Fund for Nature (WWF). In this second phase, the initiative adds 20,000 square meters of restored area, more than doubling the total to over 40,000 square meters.

The “Ocean Box Partners” project emphasizes broader collaboration to engage more participants. Over 52 partners have joined the network, including JD Supermarket, JD Foundation, and global brands such as Haier, Yili Group, Swire Coca-Cola, and Burberry.

Its standout feature is the close integration of conservation with everyday consumer participation. On Green Stream Day (July 6, 2025), with WWF technical support, JD.com linked its online mangrove nurturing platform to customers’ loyalty points. Shoppers can now redeem routine purchases to directly nurture mangrove growth, building on a previous digital campaign that drew over 5 million participants and establishing a compelling “shop-for-good” model that delivers shared benefits.

Built on Strong Sustainability Foundations

Ocean Box Partners draws strength from years of systematic progress under the Green Stream Initiative, which promotes comprehensive green transformation throughout the supply chain to facilitate a seamless shift toward low-carbon operations.

For instance, JINGDONG Logistics has transformed its operations with 139.22 MW of installed solar capacity across facilities by the end of 2024, more than 10,000 new-energy vehicles in its self-operated fleet, and in 2024 alone, 860 million reduced-packaging cartons, 960,000 reusable insulated boxes, and over 290 million recycled cartons.

This international recognition at UNEP headquarters affirms JD.com’s dedication to sustainability. As the Green Stream Initiative demonstrates, true sustainable branding goes beyond messaging—it demands transforming operations with integrated responsibility, supply chain excellence, and ecosystem care. We will continue advancing it to lead eco-friendly consumption and logistics, and set a global standard for responsible supply chains, providing practical, scalable inspiration for companies worldwide building resilient and responsible brands.

(vivian.yang@jd.com)

Stay up to date on the latest news from JD.com

Enter your email address to subscribe to this blog and receive notifications of new posts by email.

Six-Year Journey of JD.ID: Annual Compound Growth Rate Doubles the Industry Average

Six-Year Journey of JD.ID: Annual Compound Growth Rate Doubles the Industry Average