Aug 19, 2022| ESG, JD Logistics

JD Logistics Put Battery Swapping Vehicles in Use

by Yuchuan Wang

JD Logistics officially put into use battery swapping vehicles on August 15. Since the company began trial operations in March, JD Logistics has deployed such EVs across China and became China’s first logistics enterprise that adopts battery swapping EV at a large scale. By the end of 2022, 1,000 battery swapping EVs will be in use.

As the end of 2021, JD Logistics used approximately 20,000 new energy vehicles in over 50 cities in China including hydrogen energy vehicles, reducing CO2 emissions by 400,000 tons annually. Additionally, the battery swapping solution is expected to increase the electricity consumption ratio by 25 percent in logistics parks, reducing the number of vehicles by 20 percent and carbon emissions by 15 percent for each vehicle, with the comprehensive carbon emissions reducing by 35 percent.

Jointly researched by JD Logistics and Quanlucheng Logistics Technology, the battery swapping solution utilizes the universal battery pack that can be adapted to different kinds of vehicles. The pack is designed to be flexible and can be upgraded to cleaner energy. At the same time, it does not require any upgrade of the existing power grid and can be adjusted to be connected with logistics parks’ distributed energy systems quickly and easily.

In the future, JD Logistics will use GHG protocol to track and calculate the enterprise’s full-chain greenhouse gas emissions, and leverage blockchain and digital platforms to track and manage these emissions, so as to receive the carbon integral certification by international carbon emission reduction organizations.

Feb 10, 2026| JD Logistics, JD Worldwide

JD.com announces JoyExpress, a new delivery service for Europe

- Fleet of JoyExpress vehicles now on Europe’s roads, delivering parcels to your door

- Last-mile express delivery team to give customers seamless and trusted experience

- JoyExpress initially supporting Joybuy, JD.com’s new online retail business in Europe

London, UK – 10 February, 2026 – JD.com, Inc., China’s largest retailer by revenue, today announces JoyExpress, its dedicated express delivery service in Europe. JoyExpress is part of JINGDONG Logistics (HKEX:2618 – ‘JD Logistics’, Inc.), JD.com’s leading technology-driven, supply chain solutions and logistics services provider.

JoyExpress will support Joybuy, JD.com’s new online retail business in Europe, which is currently in the beta testing phase, prior to launching in March 2026. Offering same-day and next-day delivery in major cities, and drawing on its advanced logistics infrastructure, the JoyExpress teams based in the UK , Germany, the Netherlands, and France, will ensure high-quality branded products are delivered quickly, efficiently and reliably. A JoyExpress integrated delivery and installation service for large home appliances will be available in major cities.

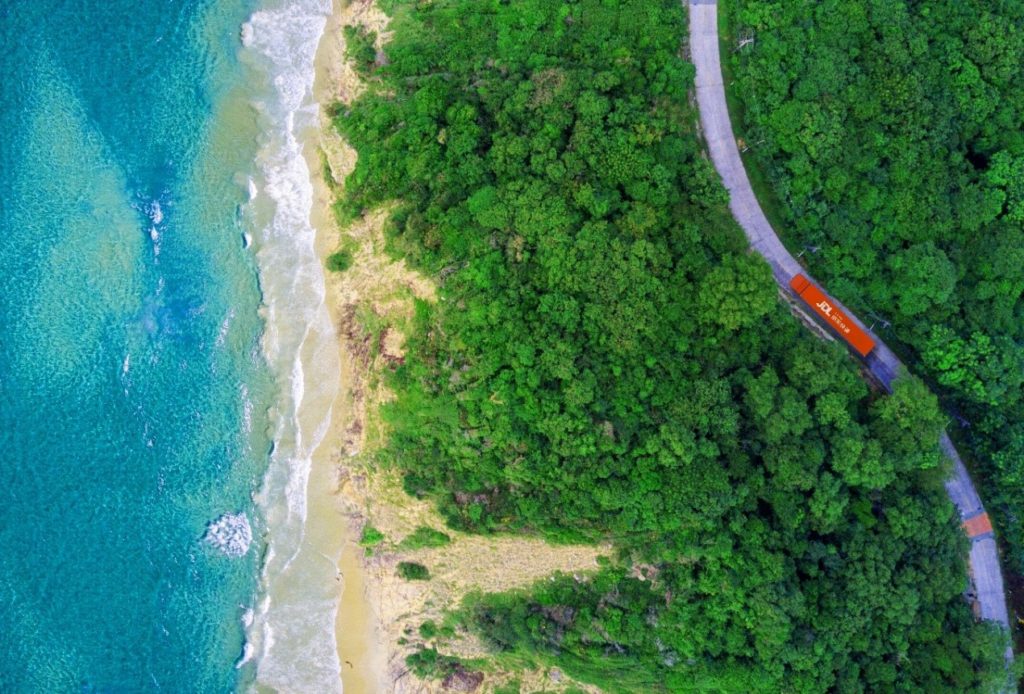

The JoyExpress team will deliver in branded uniforms and vehicles, reflecting the company’s commitment to professionalism and customer-first excellence. The JoyExpress fleet includes a range of trucks, vans and electric bicycles, operating from more than 60 warehouses and depots across Europe, a number which will continue to grow as the Joybuy service is rolled out to more cities across the continent.

This slideshow requires JavaScript.

JoyExpress is underpinned by an integrated service covering warehousing, transportation, large-item logistics, cold chain and end-to-end supply chain management and technology solutions. Supported by industry-leading intelligent warehousing, automation technologies, and data-driven operations, JoyExpress enables faster, more reliable, and more sustainable logistics performance for businesses and customers.

“JoyExpress offers Europe a new delivery and logistics choice,” said Axel Eggenwirth, Senior Director, Last Mile Europe, JINGDONG Logistics. “We look forward to bringing our industry-leading technology and capabilities to the market and consumers across France, Germany, the Netherlands and the UK, while enhancing our supply chain logistics capabilities in sectors such as electronics, home appliances, fast-moving consumer goods and groceries.

“With JoyExpress, Joybuy customers will have access to a cutting-edge, world-class fulfilment team for all their delivery needs. JoyExpress will help deliver Joybuy’s seamless, trusted, and joyful shopping experience to customers in Europe. JoyExpress will offer speed in every step, joy in every box.”

JoyExpress will initially focus on Joybuy, but in the future, JoyExpress will offer delivery support to business partners.

About JINGDONG Logistics

JINGDONG Logistics (HKEX:2618 – JD Logistics, Inc.) is a leading technology-driven, supply chain solutions and logistics services provider. Through its international logistics brands, JoyLogistics and JoyExpress, the company delivers integrated services covering warehousing, transportation, last-mile delivery, large-item logistics, cold chain, cross-border logistics, and end-to-end supply chain management and technology solutions. With industry-leading intelligent warehousing, automation technologies, and data-driven operations, JINGDONG Logistics enables faster, more reliable, and more sustainable logistics performance for businesses and consumers globally. Founded in 2017, JINGDONG Logistics builds on JD.com’s in-house logistics operations that began in 2007.

JINGDONG Logistics is building a global smart supply chain network featuring local warehousing and integrated international transportation capabilities. As of September 30, 2025, the company had a network of over 1,600 self-operated warehouses and 2,000 third-party owner-operated cloud warehouses, across 24 markets, with a total gross floor area of more than 34 million square meters. Globally, JINGDONG Logistics operates over 130 bonded, international direct distribution and overseas warehouses.

About Joybuy

Joybuy is JD.com’s online retail business in Europe, offering high-quality brands, delivered from its own warehouses to the customer’s doorstep, through a speedy and reliable network. Joybuy places the customer at the heart of everything it does. The Joybuy slogan “Don’t just buy, Joybuy”, perfectly captures the mission to fulfil customers’ needs and provide a service that is easy and convenient, but also enjoyable and fun.

Joybuy is currently in the beta testing phase and plans to launch in 2026, when it will provide a more joyful shopping experience in the UK, Netherlands, Germany, France, Belgium and Luxembourg.

About JD.com, Inc.

JD.com, Inc. (NASDAQ: JD and HKEX: 9618), also known as JINGDONG, is a leading supply chain-based technology and service provider. The company’s cutting-edge retail infrastructure seeks to enable consumers to buy whatever they want, whenever and wherever they want it. The company has opened its technology and infrastructure to partners, brands and other sectors, as part of its Retail as a Service offering to help drive productivity and innovation across a range of industries. JD.com’s business has expanded across retail, technology, logistics, health, industrials, property development and international business.

JD.com is ranked 44th on the Fortune Global 500 list and is China’s largest retailer by revenue. The company has been listed on NASDAQ since 2014, and on the Hong Kong Stock Exchange since 2020. Committed to the principles of customer first, innovation, dedication, ownership, gratitude, and integrity, the company’s mission is to make lives better through technology, striving to be the most trusted company in the world.

Contact:

Media email contact: press@jd.com

Jan 28, 2026| JD Logistics

From Fixed Capacity to Elastic Fulfillment: How JINGDONG Logistics’ LangzuTech Goods-to-Person System Redefines Smart Warehousing

- Modular, zone-based deployment allows warehouses to scale outputup or down with demand, reshaping fulfillment cost structures.

- Goods-to-person design leverages up to 12 meters of clear height, significantly increasing storage density and reducing warehousing cost per unit.

- Successfully deployed across apparel, pharmaceuticals, electronics, FMCG, and full-category warehouses with complex order profiles.

As e-commerce and omnichannel retail continue to evolve globally, logistics and supply chain operators are facing unprecedented operational complexity. Rapid SKU expansion, frequent assortment changes, and extreme order volatility, particularly during peak sales events, are placing growing pressure on traditional warehouse models built around manual labor and fixed capacity.

To address these challenges, JINGDONG Logistics has developed the LangzuTech Tote Handling, a Goods-to-Person (G2P) system.

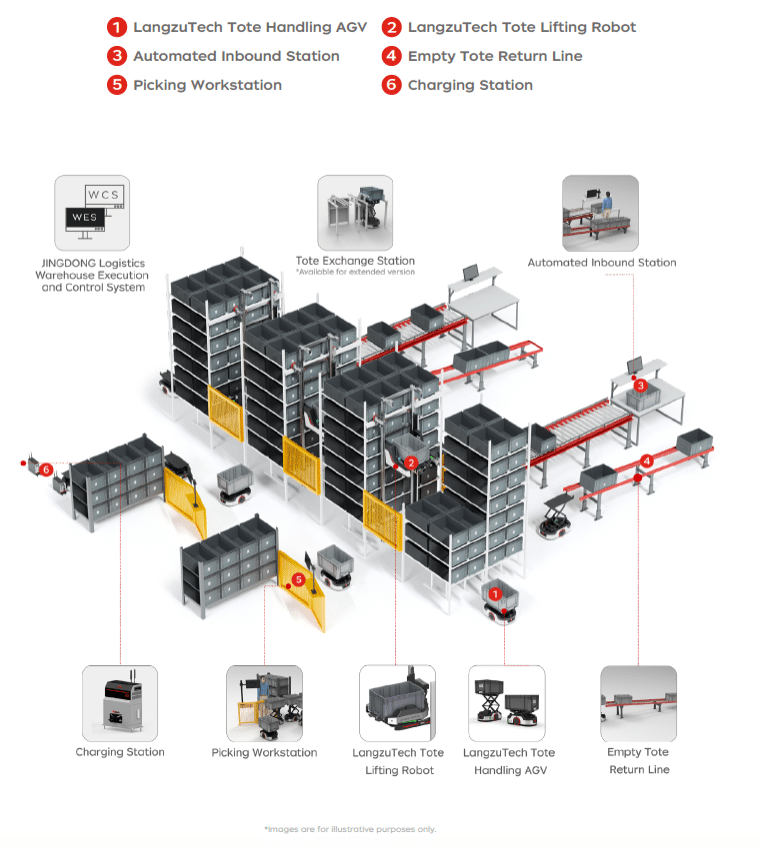

An Integrated Goods-to-Person Architecture Built for Density and Accuracy

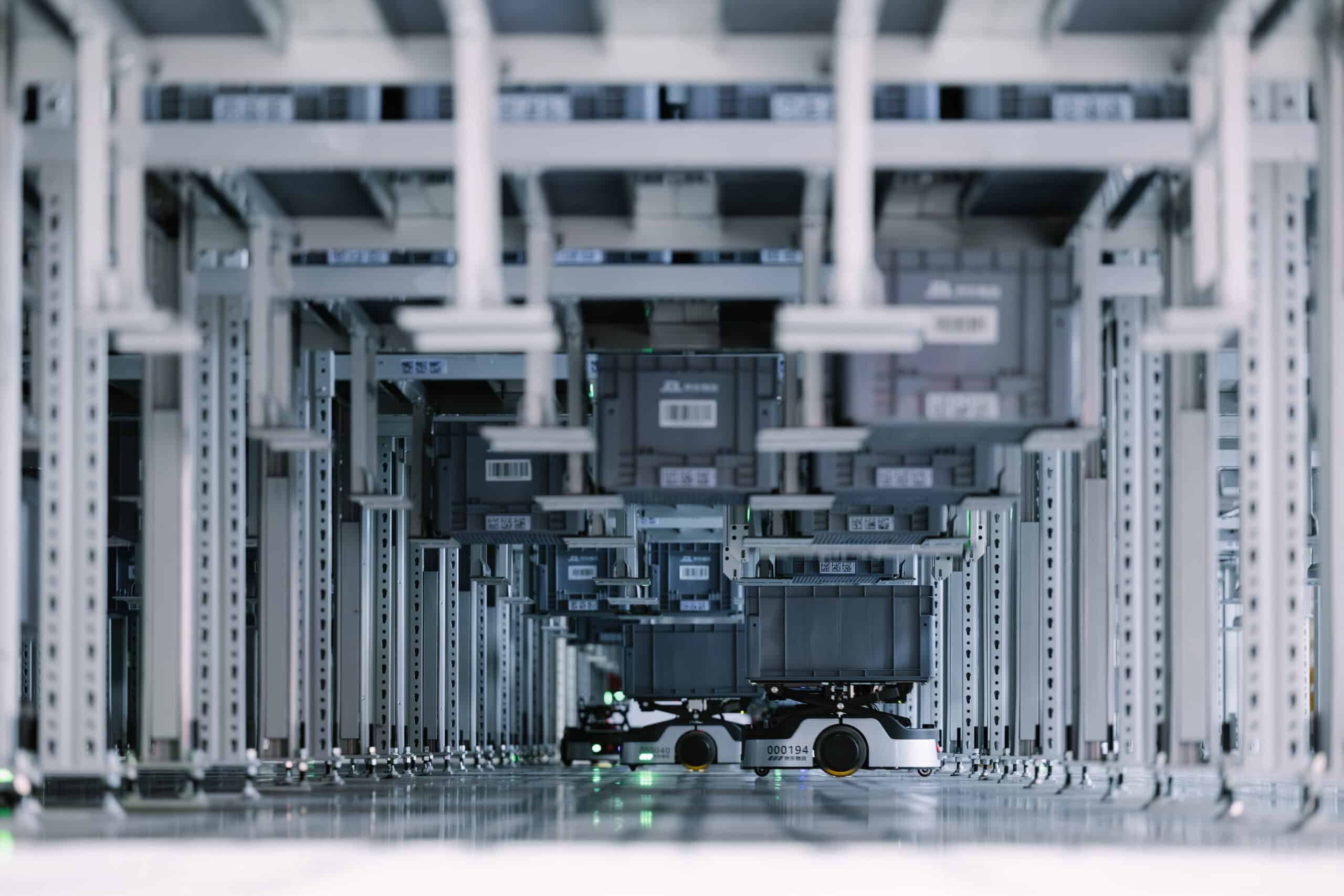

LangzuTech Tote Handling System is a fully integrated G2P solution that combines tote-handling AGVs, lifting robots, high-density three-dimensional racking systems, automated inbound and picking workstations, empty tote return lines, and centralized charging stations into a closed-loop operational flow.

Through intelligent spatial reconfiguration, the system maximizes the use of a clear height under 12 meters, enabling high-density storage that significantly increases space efficiency and lowers unit warehousing costs. Unlike traditional warehouses that rely on strict category-based zoning, it supports multi-SKU, multi-category storage within a single tote, minimizing consolidation and improving order assembly efficiency in mixed-order environments, while fully leveraging warehousing space.

Modular Deployment for Faster Time to Value

Unlike conventional automated warehouses that require large upfront investment and rigid capacity planning, LangzuTech Tote Handling System adopts a modular, building-block design. Warehouses can deploy the system by zone, implement it in phases, and scale capacity by flexibly adding or redeploying robots and workstations as demand fluctuates.

This allows operators to increase investment as their business grows. As a result, automation upgrades integrate smoothly into live operations, minimizing disruption while accelerating return on investment.

By shifting from labor-intensive, fixed-capacity models to a more agile, technology-driven framework, JINGDONG Logistics fundamentally reshapes the cost structure of fulfillment operations and lowers the entry barrier to intelligent warehousing for businesses of various sizes.

Proven Across Complex, Multi-Category and Regulated Environments

The solution has been successfully deployed across a wide range of industries, including apparel, e-commerce, pharmaceuticals, consumer electronics (3C), FMCG, and beauty.

In large-scale apparel fulfillment centers, where rapid onboarding of new SKUs and fast shelving are critical, it enables five- to sixfold improvements in inbound shelving efficiency without expanding warehouse footprint. In one high-volume apparel operation, hundreds of robots operate collaboratively across dense storage aisles and multiple workstations, supporting daily outbound peaks of over 30,000 orders while significantly improving fulfillment speed and stability.

In pharmaceutical applications, LangzuTech Tote Handling System delivers both efficiency and compliance. Each product is assigned a unique traceability code when it arrives, enabling end-to-end inventory visibility. The system automatically manages storage rules for cold-chain, light-sensitive, and regulated products, while continuously monitoring temperature and humidity. Near-expiry inventory triggers automated alerts, eliminating the need for manual inspections. By leveraging high-density storage and robot-driven handling, a pharmaceutical warehouse using the solution has achieved:

- Up to 4× storage density on the same footprint

- 99% picking accuracy

- Up to50% reduction in per-order handling costs

Order consolidation across multiple downstream outlets further shortens outbound lead times and strengthens overall supply chain responsiveness. In pharmaceutical operations in China, a LangzuTech-powered warehouse feeds hundreds of downstream retail pharmacies in the Beijing region. Without having to expand warehouse footprint, the overall processing capacity has increased by approximately 600%, compared with pre-automation operations.

LangzuTech Tote Handling Solution has now entered a phase of large-scale replication and deployment, supporting JINGDONG Logistics’ broader vision of building efficient, resilient, and sustainable supply chains worldwide.

As JINGDONG Logistics continues to expand its global warehouse network, which now includes more than 130 overseas, bonded and direct mail facilities worldwide, the LangzuTech solutions provide a standardized, yet flexible automation foundation that can be adapted to diverse regulatory, operational, and industry environments.

Stay up to date on the latest news from JD.com

Enter your email address to subscribe to this blog and receive notifications of new posts by email.

JD.com and OPPO Deepen Partnership

JD.com and OPPO Deepen Partnership