Oct 30, 2020|

Behind the Scenes of JD’s Asia No. 1 Fulfillment Center Network

by Ella Kidron

Leo Xia, head of JD’s Asia No. 1 fulfillment center project, gave an in-depth overview on September 9th of the project to top consultancy Gartner. Thomas O’Connor, senior director at the supply chain center at Gartner moderated the discussion. The exclusive peek behind the scenes has now been made available to the public here.

Leo Xia, JD.com

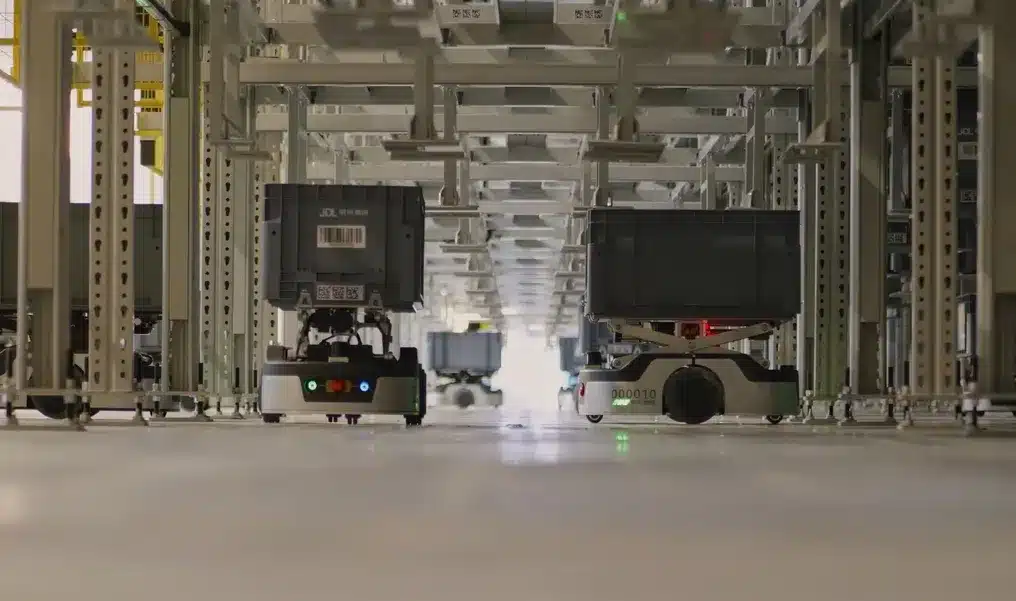

JD started preparing to build its automated logistics fulfillment center in July 2009, called Asia No. 1. As the name indicates, the plan was to build the largest scale and most advanced network of e-commerce logistics centers in Asia. The ultimate goal is to increase efficiency and reduce costs. Today the network has over 30 fulfillment centers across China.

In 2012, JD took the lead in building the first e-commerce operations center, integrating temporary storage, order processing, sorting and distribution. It come into operation in 2014, around the time of JD’s IPO on the Nasdaq(May 22nd ,2014). The following year, the first Asia No. 1 to handle small items was put into operations in Guangzhou. With the rapid growth of JD’s business, the speed of construction of Asia No. 1 projects has also sped up.

The Asia No. 1 project in Beijing is a good example. This project began operations in 2017. The automated equipment includes a 19-storey shuttle system, which greatly improves storage capacity. Picking is also much more efficient. Compared with manual picking, automated picking is 6-8 times more efficient. Storage efficiency is also 10 times that of traditional storage.

Gartner Webinar

As far as automated sorting goes, JD’s Wuhan Asia No. 1 provides a helpful picture. The project was put into operation in 2019, and uses an industry-leading large-scale cross-belt sorting system and a high efficiency sorting system. The capacity of a single sorting facility can reach 24,000 items per hour. Twenty-four sorting gates can operate at the same time. The daily order processing capacity of the sorting facility is over 1 million orders. What’s more, the sorting efficiency is five times higher than that of the traditional operation model.

Xia also introduced JD’s state of the art bulky storage system which is in its Langfang, Hebei province fulfillment center. It has a total floor area of 87,000 square meters. It began operating in 2020.

This is the first automated pallet storage and retrieval system, or “AS/RS”, for bulky items in Asia’s e-commerce industry. With the automated AS/RS, automated storage and picking for items including furniture and home appliances is made possible at an efficiency three times that of traditional warehouses.

To help put things in perspective: During the 618 Grand Promotion, which is the anniversary of JD’s founding as well as the largest mid-year shopping festival in China, the AR/RS was able to handle 15,000 items in 24 hours, with a maximum of 2,500 items per hour at peak time, representing an efficiency increase of 16 times. After implementing the AS/RS, the storage efficiency is 15.7 items per square meter, which is 145% more efficient than traditional storage. The efficiency of a multi-layer inbound entry is 50 pallets per hour, increased 150% compared with a flat inbound entry.

In the Q&A, Xia shared a bit on future development plans for the Asia No. 1 project and JD’s smart logistics fulfillment centers. He explained that technology application in JD’s logistics centers will continue to focus on two areas: 1) increasing effective space utilization and 2) efficiency of human labor (or work efficiency). “Different flexible dense storage systems will continue to improve the efficiency of space utilization. On the other hand, we will apply cutting-edge applications of “goods to person” technology. In the operations process (inbound, shelving, picking, inventory, outbound), we will appropriately introduce automation equipment and comprehensively improve the efficiency of human labor and our overall operations.”

Leading Chinese Farmers to a Better Life: Richard Liu’s Road of Poverty Alleviation

Leading Chinese Farmers to a Better Life: Richard Liu’s Road of Poverty Alleviation