Sep 5, 2020|

Top International Media Visit JD’s Asia No. 1 Warehouse

by Ella Kidron

JD.com hosted a group of international and English-language representatives from the media on September 4th in its highly automated Asia No. 1 fulfillment center in Beijing. The purpose of the tour was to illustrate how the high level of automation in the fulfillment center was able to ensure stable operations under COVID, as well as how it is able to respond with agility to peak shopping festivals such as the 619 Grand Promotion and Singles Day (November 11th). Several outlets such as South China Morning Post, NHK of Japan, Swedish Radio, Agence France Presse (AFP), CGTN and several US media were in attendance, with a total of over a dozen reporters joining the event.

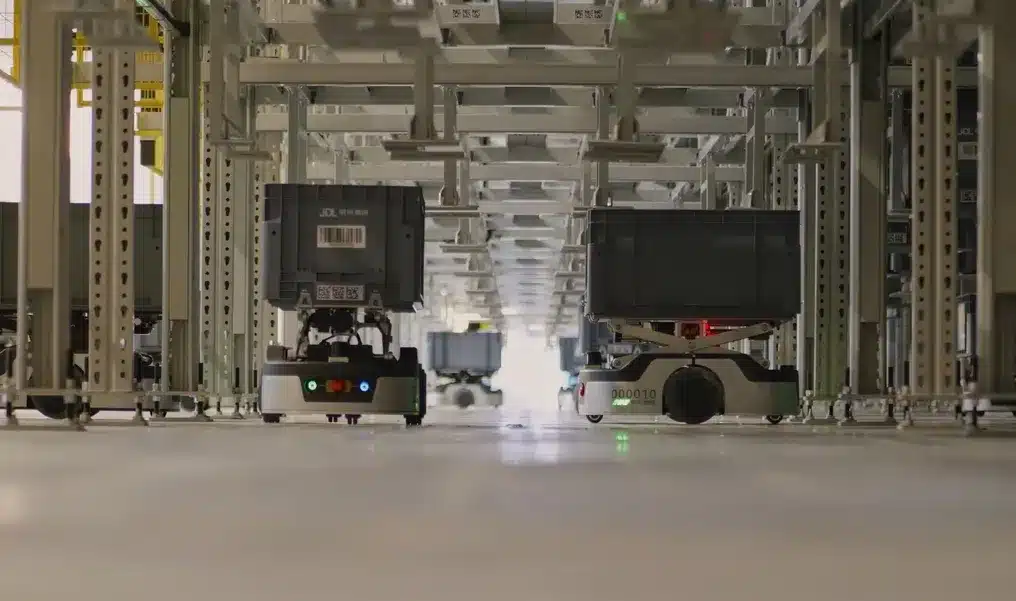

During the tour, reporters visited JD’s shuttle system, its automated ground vehicle (AGV) system called Dilang(Ground Wolf) which was developed in house, as well as the sorting facility. The tour further helped the media to understand the journey of a package from order placement down to preparation for the last mile delivery.

JD’s 19-storey shuttle system greatly improves storage capacity. Picking of goods is also made much more efficient. As compared with manual picking, the shuttle system enables a “goods to person” model, where the products for a given customer order will be retrieved automatically. Automated picking is six-to-eight times more efficient than manual picking. Storage efficiency is also 10 times that of traditional storage.

The “Dilang” AGV researched in-house by JD logistics is used for picking goods. A logistics firm in Germany has ordered a whole set of AGV last month from JD to be installed at their warehouse. The AGVs can recognize QR codes on the floor and use them for route planning as well as automatic obstacle avoidance. The pickers can stay on the working platform and wait for the AGVs to come to them. With this system, pickers can pick about 250 orders per hour each, which is three times the efficiency of a traditional picking approach where the warehouse worker would have to walk to the shelf, get the goods themselves and then go back to the packing area.

Finally JD’s advanced computer vision-based sorting system ensures that all orders end up in the right place before they are sent off to the company’s delivery stations for the last mile delivery to the customer.

JD started building its first automated logistics fulfillment center in Shanghai in July 2009. As the name “Asia No. 1” indicates, the plan was to build the largest scale and most advanced network of e-commerce logistics centers in Asia. The ultimate goal is to increase efficiency and reduce costs. In 2012, JD took the lead in building the first e-commerce operations center, integrating temporary storage, order processing, sorting and distribution. It came into operation in 2014, around the time of JD’s IPO on the Nasdaq. The following year, the first Asia No. 1 to handle small items was put into operations in Guangzhou.

With the rapid growth of JD’s business, the speed of construction of Asia No. 1 projects has also sped up. As of June 2020, JD had a total of 28 Asia No. 1 projects in operation, with eight main logistics hubs in Beijing, Shanghai, Guangzhou, Chengdu, Wuhan, Shenyang, Xi’an and Hangzhou.

CIFTIS_3: JD Business Showcases Smart Procurement Solution for Enterprises

CIFTIS_3: JD Business Showcases Smart Procurement Solution for Enterprises