Nov 5, 2020|

In-depth Report: JD Industrial Technology: The Fourth Unicorn Under JD

by Ling Cao

“JD Industrial Technology hopes to drive industry transformation based on technology, and to become the world’s largest industrial technology e-commerce platform,” Deming Ding made this remark last week.

Ding is general manager of JD Industrial Technology, a subsidiary of JD.com and a division of JD Business service unit, operates an e-commerce platform that specialized in industrial maintenance, repair and operations (“MRO”) products and services, and provides intelligent purchasing platform and supply chain solutions for corporate customers.

Deming Ding, general manager of JD Industrial Technology

JD Industrial Technology is considered as the fourth unicorn under JD.com. The previous three unicorns under JD are JD Logistics, JD Digits and JD Health. On April 24th, JD.com entered into definitive agreements for the non-redeemable series A preferred share financing of JD Industrial Technology. The total amount raised is US$230 million, bringing it to US$2 billion, and making it the highest valued domestic industrial technology company in China.

“In the long-term, we want to become the service provider of industrial IoT. This is all based on technology,” Ding added. He explained that JD Industrial Technology’s three key differentiators are technology, supply chain and operations experience.

All based on technology

Ding said, “JD can leverage AI to help clients predict procurement demand, and apply the technology for the whole process covering fulfillment, delivery, and more.”

Based on technology, JD Industrial Technology has built an AI-powered integrated procurement system for enterprise clients, enabling them to improve procurement efficiency. Enterprises can use image recognition technology to automatically recognize product images, parameters and categories, and send alerts regarding illegal operation, with an accuracy rate of up to 95%.

JD Industrial Technology has also launched a product pool to solve the industry’s pain points for non-standard product management. The pool leverages JD’s AI and big data, and experience from leading brands, so that clients can easily find and purchase specific, non-standard products on JD, for instance, a very specialized screw.

A Zhejiang based electric company Delixi Electric signed an agreement with JD in this filed in September last year. Junqian Yang, chief growth officer of the company, said “The manufacturing industry is different from other industries in that it tends to deliver on schedule, and any sudden incidents may cause irreparable consequences. That’s why factories need professional engineers on site. They also need store spare materials, meaning huge inventory costs. Cooperating with JD provides us with a smart procurement platform, enabling us to upload information on the platform. This helps us analyze the materials, predict a single device’s condition more precisely and prepare inventory in a realistic way, making the process more cost-effective.”

Delixi Electric signed an agreement with JD

Leveraging JD’s smart retailing experience, the company has also launched a smart retail store solution, which helps to standardize and digitalize offline stores. With JD’s help, offline stores can enjoy services to upgrade their brand image, rebuild their store, implement smart store systems, and more.

Building supply chain

JD has served millions of different types of clients, covering key accounts (KA), such as Fortune Global 500 companies, small and medium sized businesses (SMBs), retail companies and individuals.

“Leveraging JD’s existing self-built supply chain capabilities, we increased our business scale in a short time for standard industrial products, and now we are expanding the infrastructure development specifically for enterprise clients, especially for KA clients who have complicated demand and internal processes. We need to make sure our supply chain can meet their need,” Ding added. “The integrated supply chain infrastructure can also empower SMBs with optimized value and improved fulfillment efficiency.”

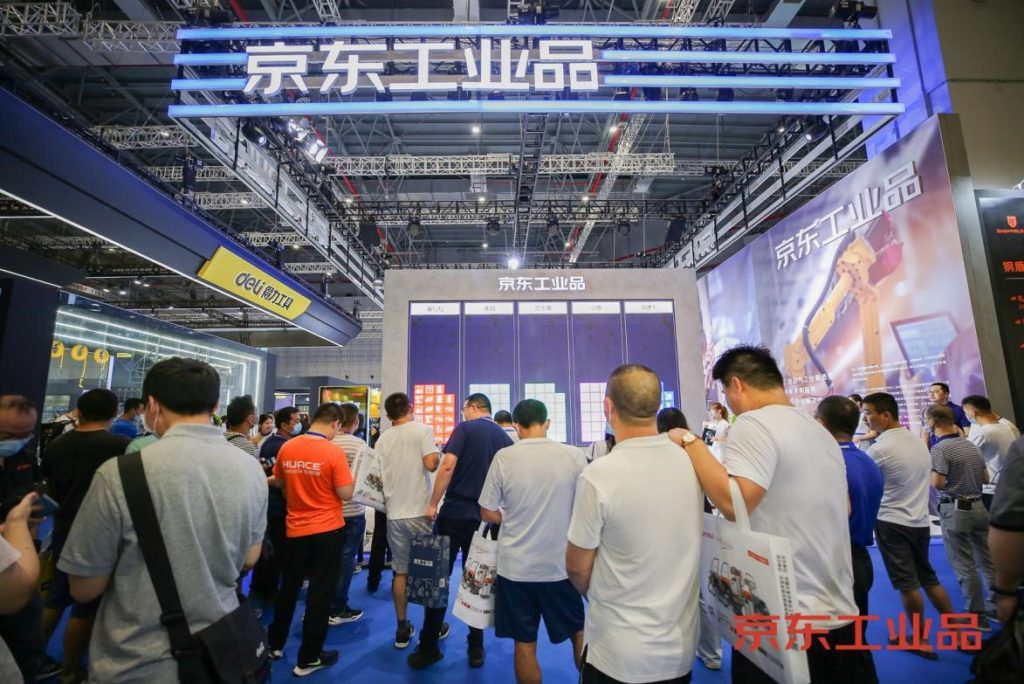

JD Industrial Technology exhibition at 22nd China international Industry Fair (CIIF) in Shanghai

Enterprise clients have different fulfillment requirements, some of which may be unexpected. To ensure fast delivery and minimize the number of touchpoints, JD will typically make multiple delivery runs per day, rather than consolidating into one. “It annoyed us to receive different packages coming from JD in multiple times in one day. Ideally, we wanted them to send in one consolidated package at a fixed time, such as once in a week, rather than the day after we placed the order. Normally we will only need these materials a week later. We just prefer to place orders in advance.” One company representative said.

The conflict is due to JD’s B2C supply chain network design. Previously, JD used the B2C supply chain system to serve B2B clients, which met several challenges, such as delivery time, special invoice requirement and more. Ding’s team observed these challenges and started to build supply chain network specifically for enterprises, including forward warehouses, special transportation fleet and post-sale services.

Operations and services

JD’s retail and marketplace models gives the company strong advantages in terms of operations. Through the retail model, JD can hold inventory and deal with manufacturers directly, allowing JD to control the whole process from pre-sale to after sales. JD is also able to provide tailored solutions for KA clients who have such requirements.

Service is one of the challenges for digitalization in this area. Ding added, “For now, many industrial e-commerce platforms can only provide transaction services, while they cannot provide the related offline services.”

JD’s Jing Gong Bang (京工帮, which literally means JD Industry Helper) was launched to address this problem. The Jing Gong Bang system provides “last mile” services to help digitalize the industry by connecting big companies with industry-leading service providers for manufacture-level omnichannel service solutions.

JD’s Jing Gong Bang program signing ceremony

Currently most clients still view JD as a platform to provide standard industrial products. More professional products such as electrical engineering materials or bearings still lack recognition from clients, but this has started to change. On JD’s super industrial technology day held last month, the company noticed that these professional products saw rapid sales growth. For example, power transmission products increased by 1200% y-o-y, and chemicals increased by 710% y-o-y. “Part of the reason is that we educated our clients about our products and services.” Ding said.

World-leading electric company Schneider Electric is a key account for JD Industrial Technology. Zhijie Xi, e-commerce director for Schneider Electric’s B2B e-commerce department said, “JD’s industrial technology solutions is a digital platform and ecosystem, which connects resources for the entire process, which can achieve service synergy in the whole market, help upgrading the industry”.

“Going forward, we need to build a comprehensive service system covering pre-sales to post sales for professional products,” Ding added. “Only in this way can we improve clients’ loyalty.” He shared that it’s easy to buy a standard product on JD without complicated after sales service, such as masks, but for a product like a bearing, it’s necessary to provide installation service.

Future outlook

“Industrial Technology is an essential industry for JD to enter, as the company is now expanding its 2B business and lower tier markets business,” Ding shared. The industrial technology business can help JD expand its reach beyond retail. The accumulated supply chain and technology infrastructure built for enterprises can also provide input and feedback for JD’s retail middle platform as a whole.

Consistently building supply chain infrastructure and developing industrial IoT capabilities will be JD Industrial Technology’s main focuses. “We have an advantage because we own inventory. We can combine industrial IoT with real applications, such as operations management, forecasting and maintenance, as well as inventory optimization,” Ding said.

JD Industrial Technology exhibition at an offline event

According to industry data, the industrial procurement demand in China has steadily increased. Total procurement amount in 2019 was RMB 2.11 trillion yuan, and the CAGR is expected to be 4.5% in next five years. Ding said: “I hope more and more participants can join the industry together, in order to cultivate the market. Clients will ultimately make decisions based on brand awareness, service capability and price.”

This Harbin tourism boom has also spurred a surge in sales of winter apparel. JD.com’s data indicates a rapid growth in the sales of warm clothing items such as down jackets, snow boots, and thermal underwear between January 1st and 7th. The sales growth is especially pronounced in southern provinces and cities such as Jiangsu, Zhejiang, Guangdong, Sichuan, and Shanghai. Notably, tall snow boots registered a 206% year-on-year increase in transactions, while padded cotton caps and thickened long down jackets soared by 158% and 134%, respectively. Beyond clothing, travel gear has also seen a considerable uptick, with a 98% year-on-year growth in transactions for large suitcases and travel backpacks in these southern regions.

This Harbin tourism boom has also spurred a surge in sales of winter apparel. JD.com’s data indicates a rapid growth in the sales of warm clothing items such as down jackets, snow boots, and thermal underwear between January 1st and 7th. The sales growth is especially pronounced in southern provinces and cities such as Jiangsu, Zhejiang, Guangdong, Sichuan, and Shanghai. Notably, tall snow boots registered a 206% year-on-year increase in transactions, while padded cotton caps and thickened long down jackets soared by 158% and 134%, respectively. Beyond clothing, travel gear has also seen a considerable uptick, with a 98% year-on-year growth in transactions for large suitcases and travel backpacks in these southern regions.

JD Sees Purchasing Surge by Enterprise Clients during Singles Day Grand Promotion

JD Sees Purchasing Surge by Enterprise Clients during Singles Day Grand Promotion