Apr 22, 2020|

In-Depth Report: The Magic Logistics-pedia of JD.com

by Ella Kidron

It is in the everyday – the fact that even in the most trying times, goods quite simply get to where they need to go – that we can feel the ‘magic’ of logistics

When a package arrives at our doorsteps, how many of us think twice about where it came from, or how it got there? We might have a vague inkling about the journey of our package, but ordinarily, few people are likely to give the process itself much thought. For a company like JD.com, what does it take to be able to deliver over 90% of orders same- or next-day, rain or shine, to customers across China?

Logistics and COVID-19

To an extent, COVID-19 has made us a bit more conscious about the journey, or at least ‘the last mile’, in a few ways. First, we are more acutely aware of all of the touch points involved in the delivery of a single package. I have spoken to several friends in the U.S. who share that they have their cans of Lysol ready to treat every package before it enters their house, while I, here in Beijing, have also used my fair share of disinfectant on containers and delivery boxes in the last several months – for me, it is not out of distrust, but a general desire to be in control of a situation in which I have little actual control.

Second, whether an order arrives on time has gone from being a “nice to have” that we both expect and take for granted, to being the deciding factor that lets us get basic necessities like food or water, while protecting our health and wellness by staying home, or avoiding going into stores necessarily. We don’t just rely on the ability to place online orders, but on the expectation that the order will reach us as soon as humanly possible.

“Delivery” at the forefront

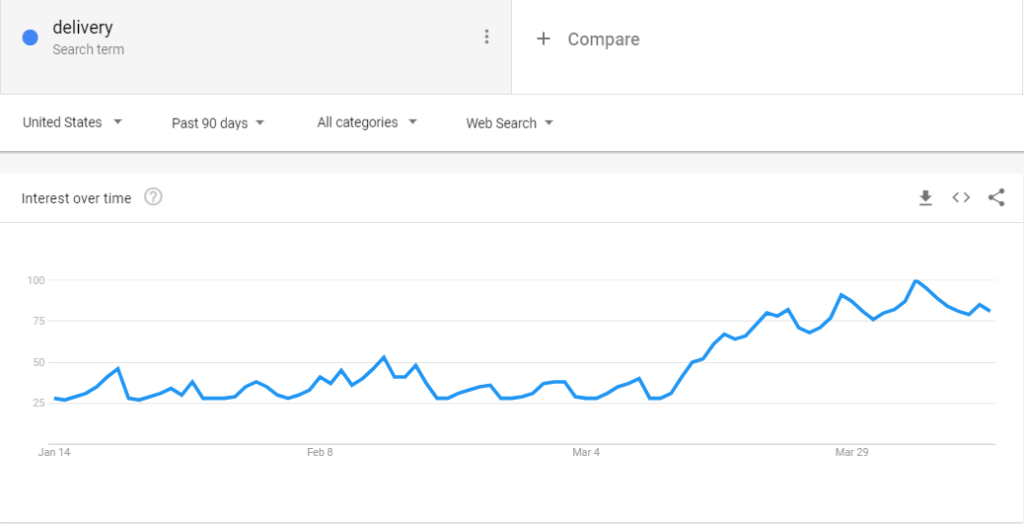

In the last month, the popularity of the word “delivery” has skyrocketed. Looking at Google Trends (for the U.S.) for the past 90 days, the term went from a score of 50 (meaning that the term is half as popular as the previous period), up to 100 in the first week of April (meaning that the term is at peak popularity).

(Source: Google Trends, April 14, 2020)

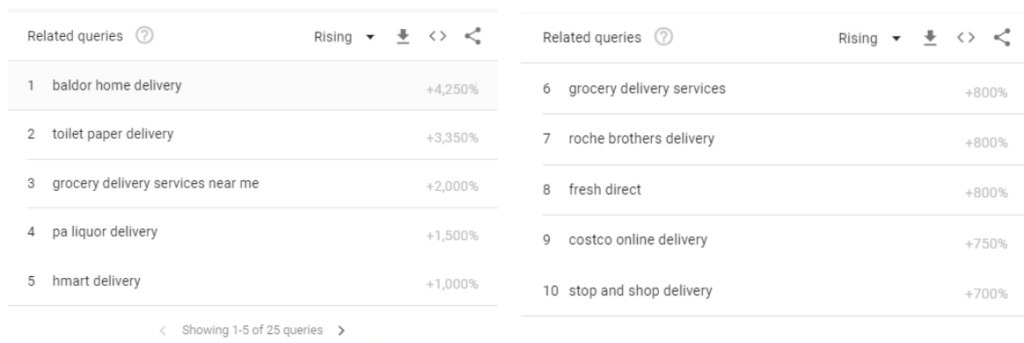

Among the most popular related queries are things like “toilet paper delivery”, “grocery delivery services near me”, “grocery delivery services”, “Fresh Direct”, “Costco online delivery” and “Stop and Shop delivery”, all of which have risen at least 700% in popularity as compared with the previous period.

(Source: Google Trends, April 14, 2020)

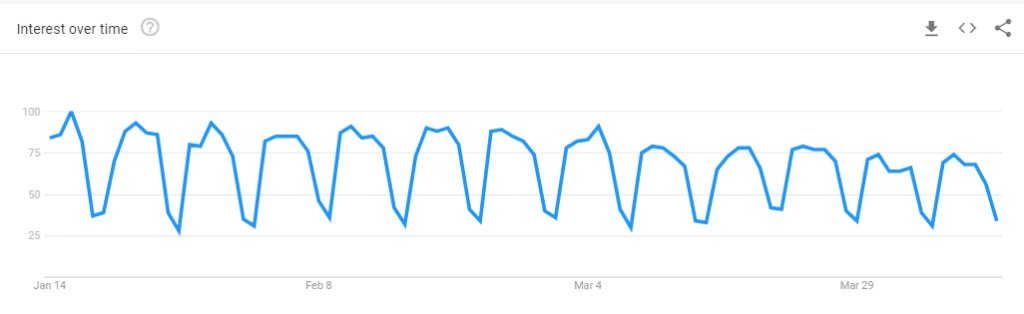

On the other hand, queries for the term “logistics” have oscillated relatively consistently throughout the same period of 90 days, rather than spiking dramatically.

(Source: Google Trends, April 14, 2020)

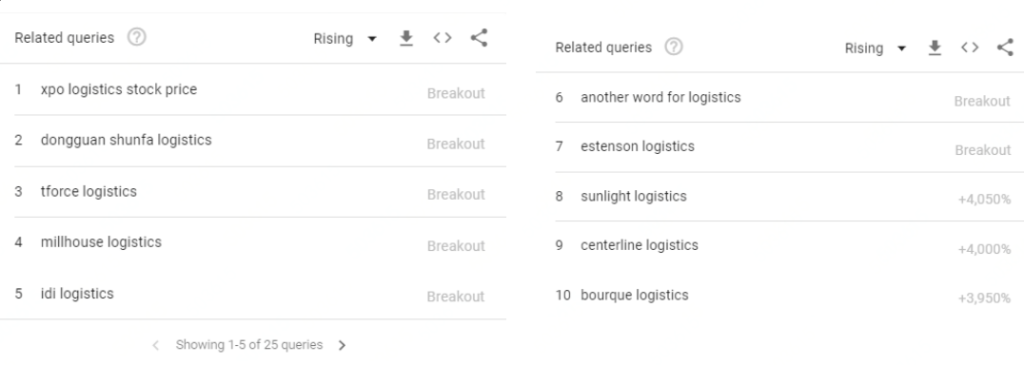

Related queries are far from commonplace every day discussion and largely focus on specific logistics companies of varying sizes. They include queries such as “xpo logistics stock price”, “dongguan shunfa”, “tforce logistics”, “millhouse logistics”, “estension logistics” and more – not exactly words that would ever come up in conversation with my grandmother, my sisters or even friends outside of this industry. Encouragingly, the term, “another word for logistics” does make the list as the 6th top related query – perhaps a quest to bring the concept into our common vernacular with a more user-friendly term.

(Source: Google Trends, April 14, 2020)

What does all this mean? Ordinarily, logistics isn’t on people’s minds because we are deceptively removed from the process, and with good reason. When there is no stress on logistics systems, and when stock is plentiful, and no pressure on delivery times, it’s easy to remain distant. After all, even if only as far as we can see, there isn’t a tangible impact on our everyday lives.

Logistics at work

Logistics, as defined by the authority on all things words, Oxford Dictionaries, is “the commercial activity of transporting goods to customers.” Yes, on the surface, it doesn’t get more humdrum or run of the mill than that – warehouses are distant lands “really far away” where no one really knows what goes on, but somewhere in between warehouses and a product’s end destination is the logistics process. But logistics is a critical part of business, and has become one of China’s largest retailer, JD.com’s competitive advantages.

To better understand how the process works, say that a customer in Beijing, China places an order for three different items from JD.com. If the items are not locally available, they will go through one of JD’s seven major regional distribution centers (RDCs). From there, items from the RDC will be transferred to a sorting center. The other part of the order, which happens to be available locally in a warehouse in Beijing, will be sourced from that respective warehouse. JD’s warehouses are intentionally located close to customers, enabling the company to deliver faster. All packages meet at JD’s delivery stations.

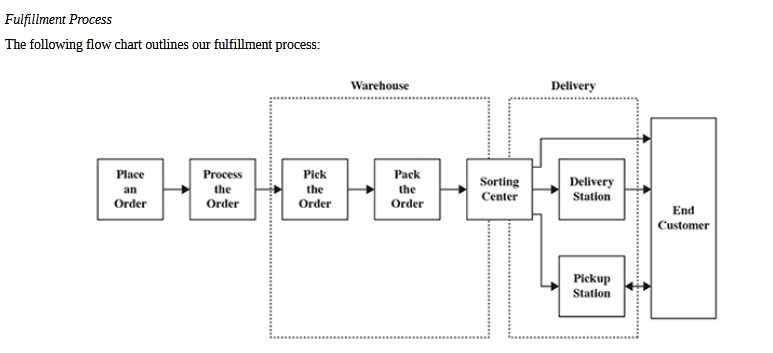

Here’s a good illustration of the fulfillment process from JD’s most recent annual report (Form 20-F):

JD’s fulfillment process as pictured in 2019 Form 20-F

Delivery stations range in size, averaging around 100 to 200 square meters, but can be much larger – for example, JD’s smart delivery station in Yizhuang where the headquarters of JD.com is also located, is 3,000 square meters, and features a computer vision-powered sorting belt helping to sort small-and-medium-sized non-fragile items. At the delivery station, the packages will then be sorted one step further, based on apartment compound or office park in some cases, and the assigned delivery courier for the area will deliver accordingly. Rather than receive a large box with small boxes inside, JD’s consolidation at the delivery station saves that step, as well as the associated packaging materials.

The entire system is trackable and completely paperless, and has been since 2014. That means there is no invoice buried at the bottom of the box with your item – everything is easily visible via an app. For retail orders, if something is ordered before 11am in the morning, it can arrive as fast as that afternoon. It really feels as painless as clicking the heels of your red shoes (cue Wizard of Oz soundtrack).

When I tell friends who don’t live in China that this is normal course of business, they don’t believe me. In fact, a popular encouragement in the fitness world is “Your body is not Amazon Prime. It’s not going to show up in two days.” In this case, it means that two days is fast, and out of the ordinary. But JD has trained consumers to expect this level of service as standard course of action. Exceptional service, along with trust that I mentioned in a previous piece, is one of the things that keeps customers coming back.

Logistics as an engine behind JD’s response to COVID-19

The above example is meant to shine a light on the ‘extraordinary’ beauty of this seemingly ordinary process. Now, perhaps more than ever, logistics is the magic behind the scenes making everything happen. As the entire world faces immense pressure in all directions from COVID-19, logistics is what ensures that emergency supplies reach hospitals on time, as well as what ensures that dinner is on the table. It has been one of the key puzzle pieces in JD.com’s response to COVID-19 across China, and support of the country’s return to work.

For eight years now, JD has been delivering consistently throughout the Chinese New Year period (when most other establishments close for one week as employees head to their hometowns to ring in the New Year with family members) to more than 300 cities across the country.

With the outbreak of COVID-19 this year, in addition to keeping its promise to deliver throughout the entire Chinese New Year period (and the entire epidemic period in general), on January 25th, JD voluntarily opened up a special channel to provide emergency relief materials to Wuhan. At the same time, priority logistics channels have been set up across the country to distribute a variety of supplies, ensuring the fastest delivery of the most urgent supplies while ensuring maximum utilization of limited capacity resources.

During the past few months JD has delivered millions of emergency medical supplies weighing tens of thousands of tons from around the world to China. At the same time, in just 40 days, from January 20 to February 28, JD sold a total of 130,000 tons of fresh food – something that relies heavily on strong cold chain logistics capabilities. In one case, JD’s extensive cold chain network helped the company to deliver over 1,300 cases of insulin donated by a pharmaceutical company to 4,900 diabetic patients during COVID-19.

JD courier delivers in Wuhan, Hubei province

Safety first

To protect the staff on the frontlines, especially in key areas, JD provided protection and prevention supplies such as masks, protective goggles, gloves and even protective clothing for delivery to the hospitals starting early on in the epidemic. At the end of December 2019, JD Logistics’ monitoring system flagged a significant increase in mask sales in Wuhan. JD Logistics immediately prepared 70,000 masks for its couriers in Wuhan and carried out rapid replenishment and internal alerts.

The company also undergoes an extensive disinfection process, disinfecting packages at each step in the process multiple times, as well as facilities such as delivery stations. At the same time, following the country’s overall guidance to minimize unnecessary human-to-human contact during the period, JD set up reminders in its app to guide consumers to choose self-pick up options.

The journey of a package under COVID-19

JD adopted systematic measures to ensure consistent operations of the supply chain during the epidemic. In a recent webinar with JD’s strategic partner, Llamasoft, Lei Zhou, strategic planning direction of JD Logistics explained that the strong logistics infrastructure and six major networks – small-and-medium sized, large, bulky, cold chain and cross-border, crowd sourced – JD has had for years helped in the response. An AI-enabled system helped JD to forecast where demand will be. Second, the fact that the company ordinarily leverages its network to put inventory nearest to customers, came in use, allowing the company to easily re-plan routes to respond to the demands of COVID-19.

Following the journey of an order for Wuhan’s famous duck neck snack (a favorite among consumers from different regions) for a customer in Beijing helps illustrate how this worked at the height of the epidemic. In this case, if Beijing’s warehouse happened to be low on inventory (meaning that the order couldn’t be fulfilled from Beijing), then it might have come from Wuhan originally. However, with the outbreak, the order might be filled from Shanghai instead as Shanghai is almost the same distance from Beijing as Wuhan.

JD’s Omnichannel Fulfillment supply chain innovation program also played a role in ensuring fast delivery to customers during the COVID-19 outbreak. Where normally demand for products like rice, flour and oil is generally higher offline, consumers turned to online sources for these items during home quarantine. With Omnichannel Fulfillment, JD matches online orders with offline supply closest to the customer in real-time and then arranges for a courier to deliver to the customer. It expanded inventory availability, enabling the company to not have to rely solely on the stock in JD’s warehouses. At one point during the virus, the daily number of orders fulfillment through the program was nearly five times that of a normal day prior to the virus.

The everyday magic of logistics

In the last few months, the return to work in China has become more pronounced. Data from JD reveals the rise in work-resumption related purchases, and also found that by the end of March, white collar workers had already resumed the habit of having e-commerce parcels delivered to their offices.

Furthermore, on April 8th, the lockdown in Wuhan, the capital of Hubei province, and the epicenter of the epidemic in China was lifted. In the first week of April alone, the number of large items delivered by JD Logistics increased over 900 percent.

According to JD data, prior to the lift of the lockdown, local residents bought large-sized products including refrigerators, treadmills, microwaves and television sets. Following the lift of the lockdown, local demand for goods which require home delivery and installation, like air conditioners and gas water-heaters rose quickly, as did large office-related purchases like tables, file cabinets and water dispensers.

So, where does that leave logistics? As more innovation and efficiency is incorporated into the logistics process through autonomous delivery robots, or delivery to trunks of cars to minimize human contact, are these innovations attracting attention because they are ‘awesome’ or are customers becoming more conscious of logistics itself? The Google Trends data doesn’t seem to suggest the latter, though perhaps that is by design.

Whether the term “logistics” becomes part of our common vernacular or not, the impact on our lives is undeniable. After all, it is in the everyday – the fact that even in the most trying times, goods simply get to where they need to go – that we can feel the true ‘magic’ of logistics. When it comes to understanding the value logistics can provide to customers, business partners and most importantly society at large, JD, as a company leading in this space in China, is one of the very best places to start.

This Harbin tourism boom has also spurred a surge in sales of winter apparel. JD.com’s data indicates a rapid growth in the sales of warm clothing items such as down jackets, snow boots, and thermal underwear between January 1st and 7th. The sales growth is especially pronounced in southern provinces and cities such as Jiangsu, Zhejiang, Guangdong, Sichuan, and Shanghai. Notably, tall snow boots registered a 206% year-on-year increase in transactions, while padded cotton caps and thickened long down jackets soared by 158% and 134%, respectively. Beyond clothing, travel gear has also seen a considerable uptick, with a 98% year-on-year growth in transactions for large suitcases and travel backpacks in these southern regions.

This Harbin tourism boom has also spurred a surge in sales of winter apparel. JD.com’s data indicates a rapid growth in the sales of warm clothing items such as down jackets, snow boots, and thermal underwear between January 1st and 7th. The sales growth is especially pronounced in southern provinces and cities such as Jiangsu, Zhejiang, Guangdong, Sichuan, and Shanghai. Notably, tall snow boots registered a 206% year-on-year increase in transactions, while padded cotton caps and thickened long down jackets soared by 158% and 134%, respectively. Beyond clothing, travel gear has also seen a considerable uptick, with a 98% year-on-year growth in transactions for large suitcases and travel backpacks in these southern regions.

JD Cloud & AI Partners with SAIC Volkswagen to Offer Smart Home Service in Passat

JD Cloud & AI Partners with SAIC Volkswagen to Offer Smart Home Service in Passat