by Ella Kidron

Many people know JD.com as a retailer – in fact, China’s largest – in recognition of its first party retail model, which is unique in China. Others refer to JD as China’s second largest e-commerce company, a gross oversimplification of the business. If you ask people who truly understand JD, however, they express an understanding that JD is not purely a retailer, but in fact a technology company with much of its technology having been first proven viable in retail scenarios.

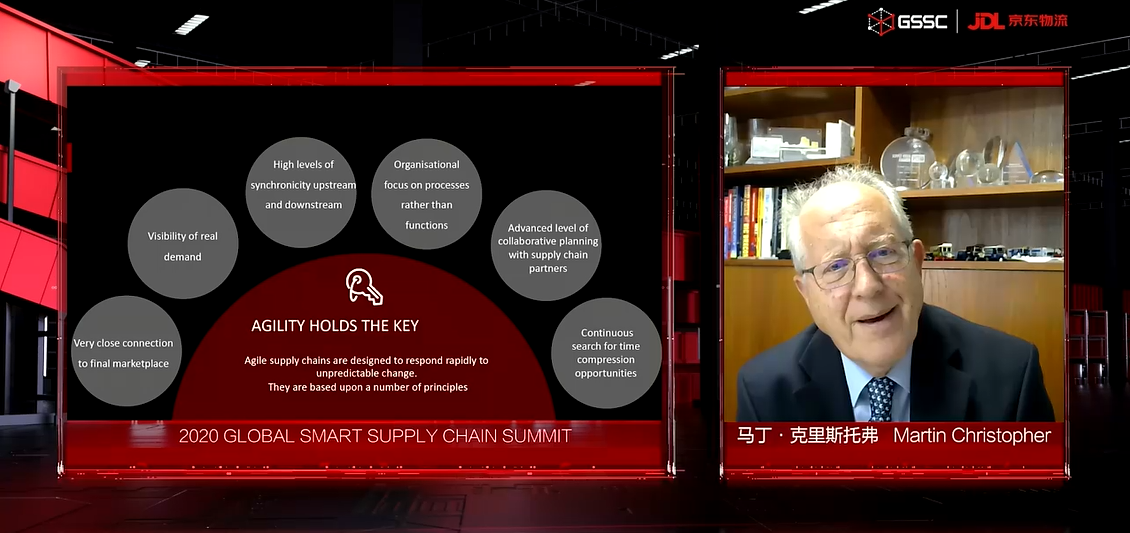

Today, JD defines itself as a technology and services company with supply chain at its core. But what does that mean in practice? There are many examples of this throughout the JD business. The announcement of mature and commercially scalable Level-4 (L4) autonomous delivery robots in Changshu, Jiangsu province, provides a classic demonstration of how JD’s capabilities, from hardware, to software, to real-world application, position the company to provide value far beyond the retail domain, and far beyond the doors of JD.com. The announcement was made at JD’s fifth annual Global Smart Supply Chain Summit (GSSC) on October 22nd, held online for the first time. Going forward, JD will work closely with Changshu, a top five county-level city in China by GDP, to develop a smart city. The company plans to put 100 delivery robots into operation in Changshu by the end of this year.

JD.com’s Level 4 autonomous delivery robot

Hardware and software

At JD’s delivery Dongnan delivery station in Changshu, a courier packs the robot with packages for the delivery run according to a system which indicates matches each secure cubby hole and its associated order. The design of the hardware, from ensuring the right size for the cubby holes based on various package sizes, to the selection of the laser beams and cameras have all been carefully overseen by JD to ensure that they will work for the intended application scenario. Furthermore, the robot has been designed to appear friendly, and approachable, making it less intimidating for consumers who are used to receiving packages directly from couriers. The robot’s autonomous driving system developed in-house and its arithmetic logic unit which has lowered the power consumption of the robot to 10% of the industry average – equivalent to that of a standard lightbulb.

From there, the robot is sent on its way. It follows routes it has planned based on the delivery addresses, ensuring the most efficient end-to-end journey. When it arrives, it sends a message to customers with a retrieval code. The robot is programmed to wait a certain amount of time, and if the customer doesn’t go pick up their package, the delivery will go back into the system and be delivered by a courier at a convenient time.

While other companies in China and globally are using robots for last mile delivery, they have yet to leave the confines of controlled traffic scenarios like university campuses. Using a robot on open roads has special considerations and algorithms and a perception system developed in-house by JD ensures smooth operation. When a robot is just going to be used in a closed park, the technology is generally similar to that of a fixed robot, which is relatively simple to develop but has limitations. But for a public road, the technology must be similar to that of a robo-taxi, which uses highly autonomous driving technology and is verified by a cloud simulation platform, which is based on accumulated data from real road conditions.

JD’s cloud simulation platform is able to discern how the robot should behave in numerous traffic scenarios –someone riding a bike against traffic, the sudden stop of the car in front, etc. – so that when it comes in contact with such scenarios it can respond quickly and act appropriately. AI-based machine learning is used to train this behavior. Qi Kong, Chief Scientist of Automation at JD Logistics, explained that the simulation platform serves to exercise the “brain” of the robot, but it needs to be combined with the “muscle memory” of actual application on the open road. That said, the robot is able to learn extremely fast. Within two hours, it can learn half a year’s worth of cases.

Simulation platform for autonomous delivery robots

Right now, autonomous driving is at a point where robots know to stop if the car ahead stops, however it is difficult for autonomous driving technology to discern the reason for the stop – is the car in front waiting for the light to turn green? Is it parked temporarily waiting for someone? Or has there been some sort of breakdown? Because of this, a central command center of sorts enables someone to be looking over all of JD’s robots, and have oversight into why the robot is behaving a certain way. On the command screen, people appear as undiscernible rectangles, allowing the person looking over it to see what is going on without intruding on privacy. There is no need for anyone to follow the robot as it can be monitored from afar.

From operation to commercialization

One of JD’s key tenets in developing technology is to avoid a steep learning curve for the end user. Technology should be used to improve experience, increase efficiency and decrease costs. This is true of the autonomous delivery robots. Jie Wang, a courier with a personal interest in technology volunteered to be the first to “adopt” the robot for his delivery. Through the Adoption Program, JD couriers are able to use the robot to handle some of their deliveries freeing them up to do more pickups. Wang used to have to deliver 170-180 packages a day. The robot can cover 50% of Wang’s deliveries to office buildings, residential compounds and universities, giving him more time to do more pick-ups (thanks to the opening up of JD Logistics to parties beyond JD Retail, businesses and individuals can also use JD Logistics’ to send packages) and earn more income. Wang’s income increased by over 30% in September alone. The robot can travel as far as 50 km on a single charge, but is intended to take more frequent, shorter trips.

JD began researching autonomous driving technology and released its first autonomous delivery robot in 2016. Earlier this year, in the face of COVID-19, the company deployed version 4.0, which was the world’s first L4 autonomous delivery robot to be put on public roads without human interaction, in Wuhan, the epicenter of the outbreak in China. During its 107-day deployment in Wuhan, the robot was used to make contactless deliveries to the hospitals in an effort to reduce cross-contamination. It traveled over 6,800 kilometers and delivered over 13,000 packages. The saying goes that “luck is when preparation meets opportunity”. While the coronavirus was by no means welcomed, the need for contactless delivery under a highly contagious virus, has demonstrated the long-term viability of autonomous delivery robots for last mile delivery. Previously, autonomous driving technology was more of a “nice to have” – a demonstration of technology prowess – in the short term, with potential in the long-term. With the coronavirus, the need for deployment and further development has become more imminent.

The autonomous delivery robot in Wuhan

Through several iterations and improvements in the technology in the last several years, JD is already at a point where its technology can be commercialized. Today, its robots are one third of the original price and that cost will continue to decline with increased scale.

JD has already demonstrated and realized the commercial potential of this technology. A partnership announced between JD Logistics and King Long, a leading bus manufacturer in China, will see JD contributing the autonomous driving system, operations platform and relevant standards to a joint project to research and manufacture commercial use low-speed autonomous delivery vehicles.

More than meets the eye in tech application

Autonomous driving technology just scratches the surface of JD’s technology capabilities. Take for example, this upcoming Singles Day (November 11th) and the associated grand promotion. Before customers have even placed an order, JD’s algorithms are calculating the likelihood of consumers in certain areas buying particular products and mapping out inventory according to those calculations, or advising its brand partners on an inventory allocation strategy ahead of the sale.

For pre-sale products, JD will put some of the stock in delivery stations nearby residential compounds of business centers, making the end delivery stations as warehouses so that consumers will be able to receive their products in minutes even during the busiest shopping season. When the customer places an order, JD again determines where to source that order so that it can be delivered as quickly as possible, in the most efficient way possible. The algorithms that determine where a product should be placed and the route it should take, are simplified into highly accessible information on the customer front – real time tracking of every touch point in the delivery process, including the name and phone number of the courier who will deliver the package.

In some cases, JD’s Omnichannel Fulfillment system will determine that said product is in fact located at a partner offline store near the customer, and instead of fulfilling the order from a JD warehouse, it will be delivered by the partner store, possibly located just steps away from the customer.

Spikes in demand for certain products will also send signals to the systems for restocking, or for a need to stabilize prices. Take for example when JD’s supply chain team noticed a spike in mask sales at the very start of the COVID-19 outbreak. With the information in hand, the team was able to reallocate mask supply to the places where it was needed most.

Tech meets healthcare

JD Health, JD’s healthcare subsidiary, combines medical and health e-commerce, internet-based medical services, intelligent hospital solutions and consumer healthcare services. Leveraging JD.com’s core strength of supply chain, JD Health has become the largest online pharmaceutical retailer in China, accounting for more than 15% of the market with extensive presence in B2C (Business-to-Consumer), B2B (Business-to-Business) and O2O (Online-to-Offline) services. Of the many technological applications at JD Health, the company uses an AI-integrated system called PharmCOO (“Pharma chief operating officer”) to optimize the clinical prescription process and improve patient safety.

At the core of the prescription review system is a knowledge graph based on Peking University Third Hospital’s vast database of pharmaceutical information. The knowledge graph-based system acts as a highly attuned and comprehensive expert for pharmacists. Using JD’s natural language processing and deep learning technology, PharmCOO can provide doctors timely reminders on contraindications, and consultant on the use of various drugs and the dosage. It can draw subtle, intelligent connections between a patient’s condition, allergies to medicine and more. Unlike a unique database, the knowledge graph-based system is constantly learning from the experience of medical professionals, enabling it to improve accuracy and taking the burden off pharmacies to memorize troves of medical data, allowing them to prioritize learning the most pertinent information.

JD Health and Huaxi second hospital of Sichuan University Jointly built an AI-powered customer service robot system to enhance patient consultation interaction experience and triage accuracy and efficiency. At present, the triage accuracy has reached more than 80%. With AI self-learning, a more accurate triage rate will be achieved in the future.

Application of digital technology

JD Digits, which will IPO on the Star market in Shanghai, combines digital technology with a rich variety of application scenarios spanning many industries. As a testament to its innovation, the company was named to Fast Company’s prestigious annual list of the World’s Most Innovative Companies for 2020 as the only Chinese company under the Data Science category. The company’s digital solutions also have been deployed across multiple sectors, including financial services, agriculture, intelligent cities, and digital marketing. For instance, JD Digits is helping financial institutions to achieve digital transformations through its one-stop financial digital solution T1 and credit card digital operation solution and intelligent asset management technology platform JT².In marketing, the company has succeeded in making digital advertising and outdoor media much more accurate and effective in reaching their audiences. Leveraging AI as core technology capability and other pillars including data, IoT, and blockchain, JD Digits is fully committed to driving forward the digitalization of industries. Over the years, JD Digits has continuously expanded its R&D investments. More than 60% of the company’s global employees are technical personnel while over 95% of its projects are focused on achieving smart and highly automated operations.

JD Cloud & AI

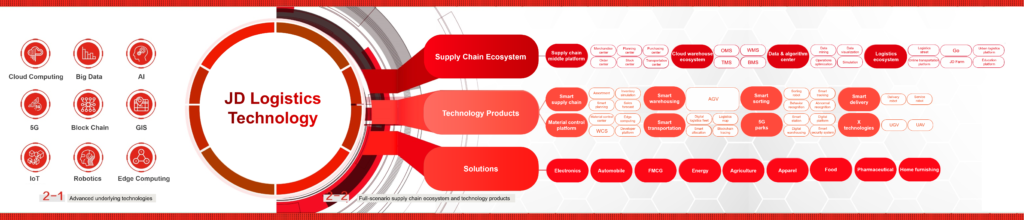

Earlier this year, JD announced that JD Cloud & AI would be the fourth core business to provide technology services, joining the ranks of JD Retail, JD Logistics and JD Digits. JD Cloud & AI, consolidates JD’s strength in advanced technologies to provide a wholesale technology solution, internally for different segments of JD.com and externally for partners.

Dr. Bowen Zhou, president of JD Cloud & AI and chair of JD Technology Committee has a clear vision for the business: “Our research and development is broken down into ABCDE (AI, Big Data, Cloud, Devices, or IoT, and Exploration). Looking more closely, if we are to imagine ABCDE as representing different parts of the human body, AI represents the brain, IoT represents the nerve endings, Cloud Computing represents the torso, muscles and blood vessels, and Big Data represents the oxygen that runs up and down the body. Finally, E is about maintaining a degree of curiosity, exploring new practices and pushing the edge of the aforementioned ABCD technologies.” The smart customer service robot developed by JD Cloud & AI which is able to sense sentiment and respond accordingly, has now been deployed across several other businesses such as most recently retail, municipal governance and medical services.

Technology, Technology, Technology

Through JD’s 16 years of development, the company has acquired extensive technological capabilities and infrastructure from retail to logistics to digital technology. JD’s R&D team now has over 18,000 personnel, among which over 80% hold masters or above degrees. In 2019, total investment by listed and unlisted affiliates of JD exceeded RMB 17.9 billion yuan (US$ 2.6 billion). Back in 2017, founder and CEO Richard Liu said it best that JD would focus on three things: “Technology, technology, technology.”

At the GSSC, Zhenhui Wang, CEO of JD Logistics, said that more than 100,000 robots will join the JD logistics family in the next five years. As demonstrated by the Changshu project and numerous others, technology represents not just a new growth area for JD, but is mapping its future development, and the impact it will have on society as a whole.

Yuchuan Wang, Ling Cao, Vivian Yang and Hui Zhang, all staff members in the Global PR Division at JD.com, contributed to this article.

(ella@jd.com)